Rocket Launch Setback: Manufacturing Flaw Exposes Critical Weakness in Vulcan Solid Motor

Manufacturing

2025-03-12 16:34:50Content

In a revealing investigation, United Launch Alliance (ULA) has uncovered the root cause behind a critical nozzle failure during the second flight of its Vulcan Centaur rocket last October. The incident, which initially raised concerns about the rocket's reliability, has now been traced to a specific manufacturing defect.

Engineers meticulously examined the rocket's solid rocket motor and pinpointed the exact source of the problem: a subtle yet significant flaw introduced during the manufacturing process. This detailed analysis provides crucial insights into the technical challenges faced in advanced rocket development and highlights the importance of rigorous quality control in aerospace engineering.

The discovery underscores ULA's commitment to transparency and continuous improvement, demonstrating their proactive approach to identifying and addressing potential technical issues. As the Vulcan Centaur program continues to evolve, this incident serves as a valuable learning experience for the team, ensuring future launches will benefit from enhanced manufacturing precision and reliability.

Rocket Science Setback: Unraveling the Manufacturing Mystery Behind Vulcan's Nozzle Failure

In the high-stakes world of space exploration, even the smallest manufacturing imperfection can lead to significant challenges. The recent revelation surrounding United Launch Alliance's Vulcan Centaur rocket highlights the critical importance of precision engineering and quality control in aerospace technology.When Precision Meets Potential: A Critical Examination of Rocket Motor Manufacturing

The Anatomy of a Rocket Motor Failure

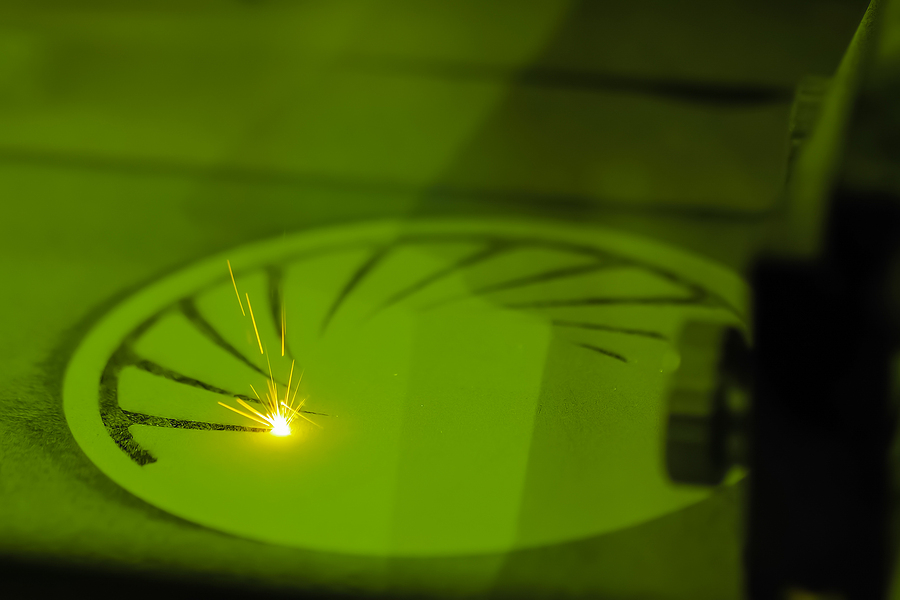

The intricate world of rocket propulsion demands absolute perfection, where microscopic defects can cascade into catastrophic failures. United Launch Alliance's Vulcan Centaur program experienced a profound setback during its second flight, revealing the unforgiving nature of space technology. Manufacturing processes in aerospace represent a delicate dance of engineering prowess and microscopic precision, where tolerances measure in fractions of millimeters and potential consequences can be measured in millions of dollars. Aerospace engineers meticulously analyze every component, understanding that a single structural anomaly can compromise an entire mission's integrity. The solid rocket motor nozzle represents a critical junction of thermal resistance, structural integrity, and propulsive efficiency. When manufacturing processes falter, the consequences extend far beyond immediate mission parameters, potentially impacting future launch capabilities and technological confidence.Investigating the Manufacturing Anomaly

Forensic analysis of the Vulcan Centaur's nozzle failure unveils a complex narrative of technological challenges. Manufacturing defects in aerospace components are not merely technical glitches but represent systemic vulnerabilities in production methodologies. The investigation likely involves microscopic examinations, material stress analyses, and comprehensive review of production protocols. Specialized materials science experts employ advanced diagnostic techniques to trace the origin of structural compromises. Electron microscopy, spectroscopic analysis, and computational modeling converge to reconstruct the precise moment and mechanism of the nozzle's structural failure. These investigations serve dual purposes: understanding the immediate incident and preventing future occurrences through enhanced manufacturing standards.Implications for Space Exploration Technology

The Vulcan Centaur incident transcends a singular manufacturing error, representing a broader dialogue about technological resilience in space exploration. Each failure becomes a critical learning opportunity, driving innovation and refining engineering approaches. Aerospace manufacturers must continuously evolve, implementing increasingly sophisticated quality control mechanisms that can detect potential anomalies before they manifest as mission-critical failures. Technological advancement emerges from rigorous examination of limitations. The solid rocket motor nozzle failure becomes a catalyst for improved manufacturing processes, more robust testing protocols, and enhanced understanding of material behaviors under extreme conditions. United Launch Alliance's transparent approach to investigating and communicating this incident demonstrates the industry's commitment to continuous improvement and technological transparency.The Human Factor in Technological Precision

Behind every rocket motor component lies a complex ecosystem of human expertise, technological innovation, and meticulous craftsmanship. Manufacturing defects are rarely isolated incidents but often represent broader systemic challenges within production environments. Skilled technicians, engineers, and quality control specialists form an intricate human network dedicated to pushing the boundaries of technological possibility. The Vulcan Centaur's nozzle failure serves as a poignant reminder of the delicate balance between human capability and technological complexity. Each manufacturing process represents a narrative of human ingenuity, where precision meets potential, and where seemingly microscopic decisions can determine the trajectory of space exploration endeavors.RELATED NEWS

Manufacturing

Tech Titan Lands: TSMC's Massive $100B Bet on American Soil Backed by Trump

2025-03-09 18:14:00

Manufacturing

Robotaxi Revolution: Tesla Ramps Up Hiring for Autonomous Vehicle Production

2025-02-24 07:41:45

Manufacturing

Silicon Surge: VCI Global's Bold Bet on India's $8.1B Semiconductor Goldmine

2025-02-27 12:33:00