From Classroom to Factory Floor: Johnstown's Bold Training Program Tackles Manufacturing Workforce Shortage

Manufacturing

2025-03-12 22:20:26Content

Johnstown Launches Innovative Robotics Bootcamp to Empower Future Manufacturing Professionals

Aspiring technologists and manufacturing enthusiasts in Johnstown are getting a unique opportunity to dive deep into the world of robotics and automation through an intensive two-day training program. This cutting-edge bootcamp is designed to equip students with hands-on skills and practical knowledge essential for success in modern manufacturing environments.

The immersive learning experience offers participants a chance to explore the latest technological advancements in industrial automation, providing a critical pathway to promising career opportunities in the rapidly evolving manufacturing sector.

By combining practical training with real-world applications, the bootcamp aims to bridge the skills gap and prepare the next generation of technical professionals for the high-tech jobs of tomorrow.

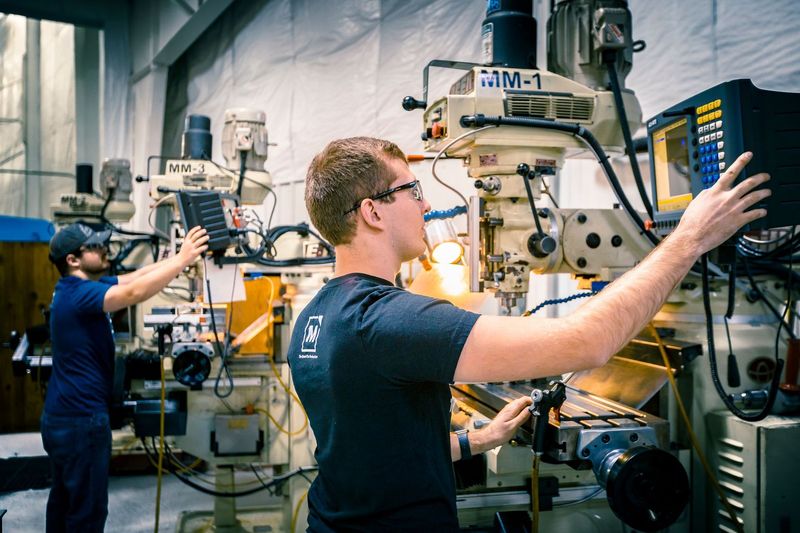

Students will have the opportunity to work with state-of-the-art equipment, learn from industry experts, and gain valuable insights into the transformative world of robotics and advanced manufacturing technologies.

Revolutionizing Manufacturing: Johnstown's Cutting-Edge Robotics Bootcamp Transforms Future Workforce

In the heart of Pennsylvania's industrial landscape, a groundbreaking educational initiative is reshaping the future of manufacturing workforce development. This innovative program represents a critical intersection of technology, education, and industrial innovation, offering aspiring professionals a transformative pathway into the complex world of advanced manufacturing and automation.Empowering Tomorrow's Technological Pioneers: Where Innovation Meets Opportunity

The Technological Renaissance in Manufacturing Education

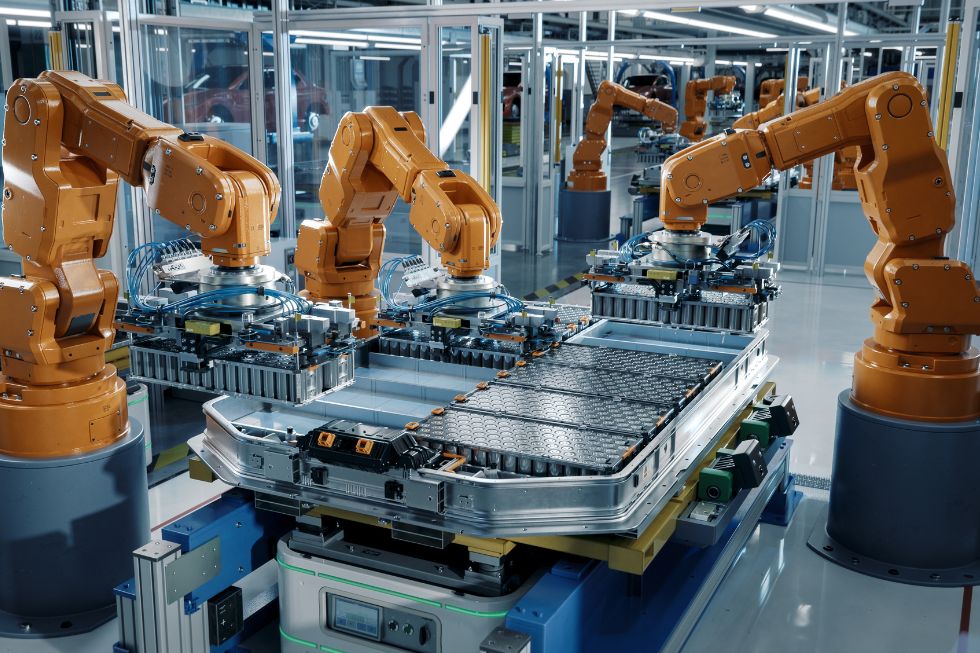

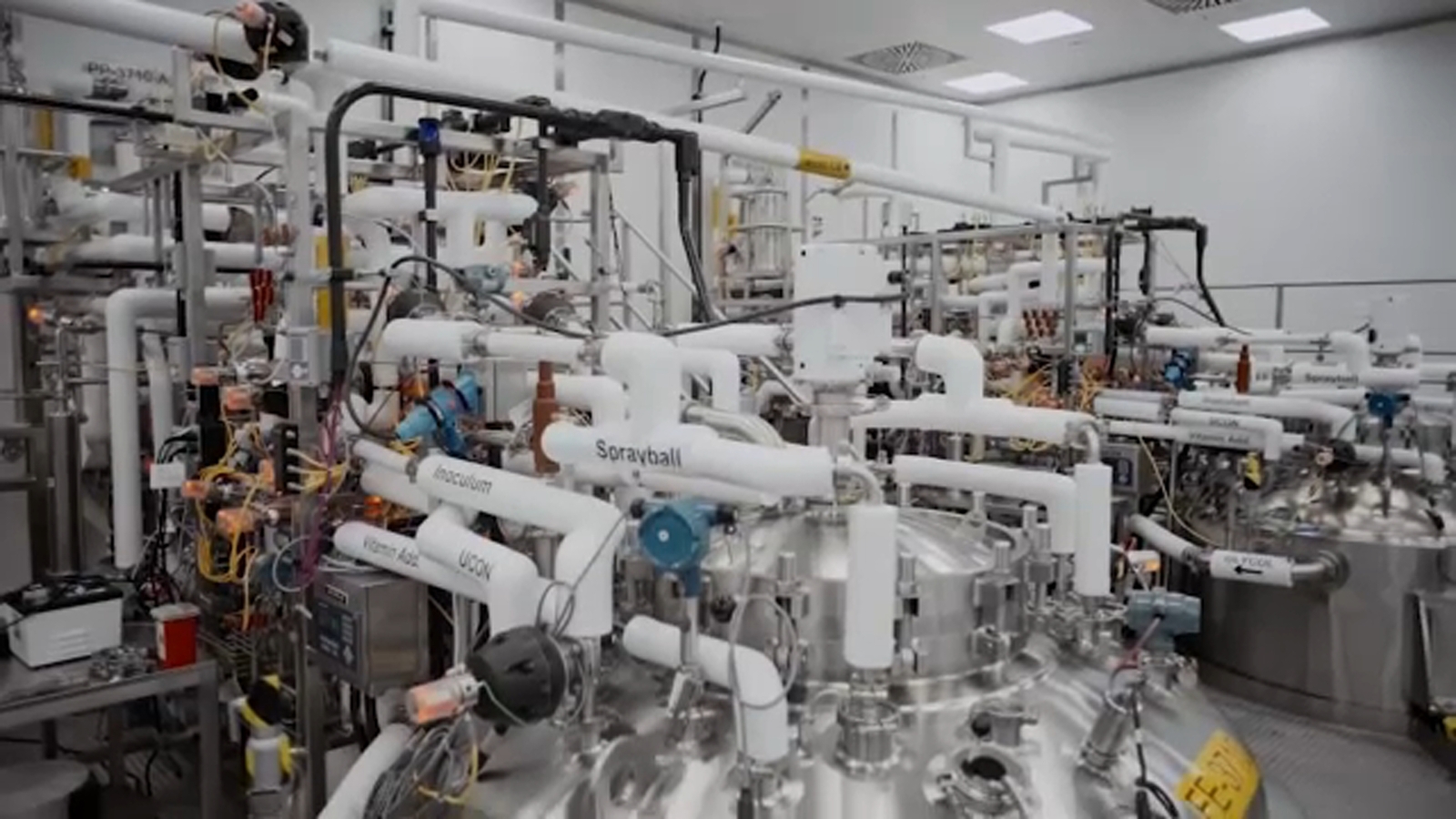

The contemporary manufacturing sector stands at a pivotal moment of technological transformation, demanding professionals who possess sophisticated technical skills and adaptive capabilities. Johnstown's robotics and automation bootcamp emerges as a beacon of progressive educational methodology, designed to bridge the critical skills gap prevalent in modern industrial environments. By providing immersive, hands-on learning experiences, the program cultivates a new generation of technologically proficient professionals equipped to navigate the intricate landscape of advanced manufacturing systems. Participants engage with state-of-the-art robotic technologies, learning complex programming techniques, system integration strategies, and advanced operational protocols. The curriculum goes beyond traditional classroom learning, emphasizing practical application and real-world problem-solving skills that are increasingly crucial in today's rapidly evolving technological ecosystem.Comprehensive Skill Development in Automation Technologies

The two-day intensive bootcamp represents a holistic approach to technological education, meticulously crafted to address the multifaceted demands of contemporary manufacturing environments. Students are exposed to comprehensive training modules that encompass robotics programming, automated system design, precision engineering principles, and advanced diagnostic techniques. Instructors with extensive industry experience guide participants through intricate technical challenges, providing insights into the nuanced world of industrial automation. The program's methodology integrates theoretical knowledge with practical demonstrations, ensuring that participants develop a profound understanding of robotic systems' operational dynamics and strategic implementation.Economic and Industrial Implications of Advanced Manufacturing Training

Beyond individual skill development, the bootcamp represents a strategic investment in regional economic revitalization. By cultivating a highly skilled workforce capable of operating sophisticated technological systems, Johnstown positions itself as a potential hub of manufacturing innovation. The program addresses critical workforce development challenges, creating pathways for economic growth and technological advancement. Local industries stand to benefit significantly from this initiative, gaining access to a talent pool equipped with cutting-edge technical competencies. The bootcamp serves as a collaborative platform connecting educational institutions, technological innovators, and industrial stakeholders, fostering an ecosystem of continuous learning and technological progression.Technological Infrastructure and Learning Environment

The bootcamp's learning environment is meticulously designed to simulate authentic industrial settings, featuring advanced robotic systems, sophisticated programming interfaces, and comprehensive diagnostic equipment. Participants interact with industry-standard technologies, gaining practical experience that directly translates to professional competencies. Specialized training modules cover diverse aspects of robotic systems, including mechanical integration, electrical systems management, programming languages, and predictive maintenance strategies. The comprehensive approach ensures that participants develop a holistic understanding of automation technologies, preparing them for complex technological challenges in various industrial contexts.Future Perspectives and Career Opportunities

Graduates of the robotics and automation bootcamp emerge with a competitive advantage in an increasingly technology-driven job market. The program's comprehensive curriculum opens doors to diverse career opportunities across manufacturing, engineering, technology, and related sectors. Participants develop a robust skill set that positions them as valuable assets in an evolving technological landscape. The initiative represents more than a training program; it is a transformative educational experience that empowers individuals to become active participants in technological innovation, bridging the gap between traditional manufacturing practices and future-oriented technological solutions.RELATED NEWS

Powering the AI Revolution: Flex Expands Texas Footprint with Cutting-Edge Dallas Plant

Lightning Strikes Twice: Ford Halts Electric Truck Production Over Critical Battery Flaw