Lilly's Game-Changing Hybrid Model: Supercharging Kisunla Production

Manufacturing

2025-02-14 23:17:22Content

Eli Lilly is revolutionizing its manufacturing approach with a cutting-edge hybrid facility designed to accelerate production of Kisunla, its promising Alzheimer's treatment. The pharmaceutical giant is strategically leveraging flexible manufacturing technologies to enhance productivity and meet growing market demands.

By implementing a hybrid manufacturing model, Lilly aims to optimize its production capabilities, ensuring faster and more efficient delivery of this groundbreaking Alzheimer's medication. The innovative approach combines traditional manufacturing methods with advanced technological solutions, positioning the company at the forefront of pharmaceutical production innovation.

The new facility represents a significant investment in Kisunla's commercial readiness, demonstrating Lilly's commitment to bringing transformative treatments to patients more quickly. This strategic move not only streamlines production but also reflects the company's agile response to complex healthcare challenges.

With this hybrid manufacturing approach, Lilly is set to improve scalability, reduce production bottlenecks, and potentially lower overall manufacturing costs. The initiative underscores the company's dedication to advancing medical treatments and improving patient access to critical medications.

Pharmaceutical Innovation Unleashed: Lilly's Strategic Leap into Hybrid Manufacturing Revolution

In the rapidly evolving landscape of pharmaceutical manufacturing, Eli Lilly and Company stands at the forefront of transformative technological integration, pioneering groundbreaking approaches that promise to redefine production efficiency and scalability in the complex world of medical innovation.Revolutionizing Drug Production: Where Technology Meets Precision

The Emerging Paradigm of Hybrid Manufacturing

Pharmaceutical manufacturing has long been constrained by traditional production methodologies, but Eli Lilly is shattering these limitations through its innovative hybrid manufacturing strategy. By seamlessly blending advanced technological infrastructure with adaptive production frameworks, the company is creating a dynamic ecosystem that transcends conventional manufacturing boundaries. This approach not only optimizes production capabilities for Kisunla, their breakthrough pharmaceutical product, but also establishes a new benchmark for operational flexibility in the industry. The hybrid model represents a sophisticated convergence of digital technologies, advanced automation, and human expertise. Unlike traditional linear manufacturing processes, this approach allows for real-time adaptability, enabling rapid response to market demands and production challenges. By integrating intelligent systems with human insights, Lilly is creating a more responsive and resilient manufacturing infrastructure.Technological Architecture of Next-Generation Production

At the core of Lilly's hybrid manufacturing strategy lies a complex network of interconnected technological systems. Advanced data analytics, artificial intelligence, and machine learning algorithms work in concert to optimize every stage of the production process. These technologies enable unprecedented levels of precision, quality control, and predictive maintenance. The implementation of such sophisticated technological frameworks allows for granular monitoring of production parameters, ensuring consistent product quality and minimizing potential variations. By leveraging real-time data insights, Lilly can make instantaneous adjustments, reducing waste and enhancing overall operational efficiency. This approach represents a quantum leap from traditional manufacturing models, positioning the company as a true innovator in pharmaceutical production.Strategic Implications for Kisunla's Market Potential

The hybrid manufacturing approach directly translates into significant strategic advantages for Kisunla's market positioning. By dramatically reducing production timelines and enhancing scalability, Lilly can respond more rapidly to emerging healthcare needs. The increased production flexibility means faster market entry, potentially accelerating the drug's availability to patients who desperately require innovative medical solutions. Moreover, the technological infrastructure supporting this hybrid model enables more cost-effective production processes. Reduced operational complexities and enhanced efficiency can potentially lower production costs, which could ultimately make Kisunla more accessible to a broader patient population. This strategic approach demonstrates Lilly's commitment not just to technological innovation, but to meaningful healthcare impact.Future-Proofing Pharmaceutical Manufacturing

Lilly's hybrid manufacturing strategy extends far beyond a singular product approach. By establishing this sophisticated production framework, the company is effectively future-proofing its entire manufacturing ecosystem. The adaptable infrastructure can be rapidly reconfigured to support various pharmaceutical products, creating a scalable and resilient production model. The broader implications of this approach resonate across the pharmaceutical industry. As other manufacturers observe Lilly's successful implementation, it is likely to catalyze a widespread transformation in production methodologies. This could herald a new era of more agile, technology-driven pharmaceutical manufacturing, with potential ripple effects on global healthcare delivery.Sustainability and Technological Innovation

Beyond operational efficiency, Lilly's hybrid manufacturing model incorporates significant sustainability considerations. By optimizing resource utilization, reducing waste, and implementing energy-efficient technologies, the company is demonstrating a holistic approach to pharmaceutical production that balances technological innovation with environmental responsibility. The integration of sustainable practices within this advanced manufacturing framework represents a progressive approach to industrial production. It signals a mature understanding that technological advancement and environmental stewardship are not mutually exclusive but can be harmoniously integrated.RELATED NEWS

Manufacturing

High-Tech Meets Factory Floor: Silicon Valley's Bold Plan to Revolutionize Manufacturing Workforce

2025-02-23 19:00:00

Manufacturing

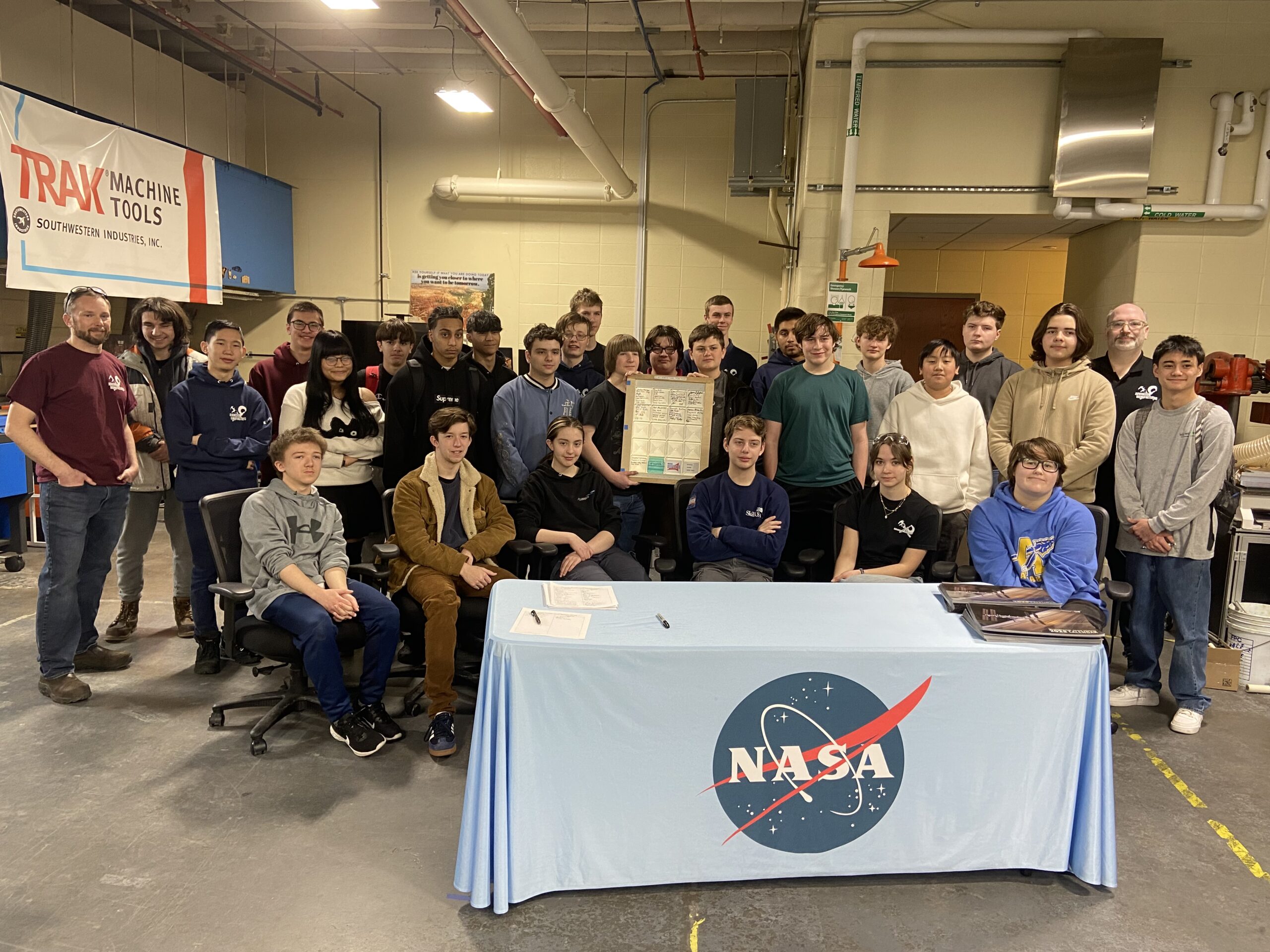

Space-Bound Scholars: Local Students' Locker Set to Orbit Earth on NASA Mission

2025-03-05 15:09:43

Manufacturing

GoldenHome Breaks Ground: Dallas Facility Marks Major North American Expansion

2025-03-06 16:45:00