Robots Revolution: How AI is Transforming the Future of Manufacturing

Manufacturing

2025-03-14 04:02:19Content

The intersection of cutting-edge research and industrial innovation took center stage at the University of Tennessee's annual Manufacturing and Reliability Conference (MARCON 2025), where artificial intelligence emerged as a transformative focal point for manufacturing professionals.

Held in Knoxville, the conference drew hundreds of industry experts, researchers, and technology pioneers eager to explore the latest advancements in manufacturing technologies. This year's event highlighted AI's growing significance, featuring compelling keynote speeches, dynamic panel discussions, and an expansive exposition showcasing vendors at the forefront of technological innovation.

As manufacturing continues to evolve, MARCON 2025 demonstrated how artificial intelligence is rapidly becoming an essential tool for driving efficiency, precision, and strategic decision-making across industrial sectors. The conference underscored the critical role of collaboration between academic research and industry practitioners in shaping the future of manufacturing technologies.

AI Revolution Transforms Manufacturing: Inside the Future of Industrial Innovation

In the rapidly evolving landscape of technological advancement, artificial intelligence is reshaping the manufacturing sector with unprecedented momentum. As industries worldwide seek transformative solutions, cutting-edge conferences are becoming critical platforms for exploring the intersection of AI, research, and industrial productivity.Unleashing Technological Potential: Where Innovation Meets Manufacturing

The Convergence of Academic Research and Industrial Application

The manufacturing sector stands at a pivotal moment of technological transformation, where academic insights and industrial pragmatism intersect with remarkable synergy. Universities are no longer isolated ivory towers of theoretical research but dynamic incubators of practical technological solutions. The recent Manufacturing and Reliability Conference (MARCON 2025) exemplifies this paradigm shift, bringing together leading researchers, industry professionals, and technological innovators to explore the profound implications of artificial intelligence. Emerging research demonstrates that AI is not merely a supplementary technology but a fundamental redesign of manufacturing processes. Machine learning algorithms can now predict equipment failures with unprecedented accuracy, optimize supply chain logistics, and create adaptive manufacturing environments that respond in real-time to complex operational challenges.Artificial Intelligence: Redefining Manufacturing Capabilities

Modern manufacturing is experiencing a radical transformation driven by AI's computational power and predictive capabilities. Advanced neural networks can now analyze massive datasets, identifying intricate patterns that human analysts might overlook. These sophisticated systems enable manufacturers to implement predictive maintenance strategies, reducing downtime and significantly improving operational efficiency. The integration of AI technologies goes beyond traditional automation. Intelligent systems can now make complex decisions, learn from historical data, and continuously improve manufacturing processes. This represents a fundamental shift from reactive to proactive industrial management, where machines become strategic partners in production optimization.The Human-Machine Collaboration Paradigm

Contrary to fears of technological displacement, AI is increasingly viewed as a collaborative tool that enhances human capabilities rather than replacing them. At MARCON 2025, presentations highlighted how AI empowers workers by handling repetitive tasks, providing real-time insights, and creating more engaging, strategic roles for human professionals. Sophisticated AI systems are now designed with intuitive interfaces that allow seamless interaction between human expertise and machine intelligence. This symbiotic relationship enables workers to focus on creative problem-solving, strategic planning, and complex decision-making while AI handles data processing and pattern recognition.Economic and Technological Implications

The economic potential of AI in manufacturing is staggering. Experts predict that intelligent technologies could generate billions in additional economic value by reducing operational costs, improving product quality, and accelerating innovation cycles. Universities are playing a crucial role in developing talent capable of navigating this complex technological landscape. Research institutions are not just studying AI but actively developing curriculum and training programs that prepare the next generation of manufacturing professionals. These educational initiatives bridge the gap between theoretical knowledge and practical application, ensuring that industries have access to skilled professionals who can leverage advanced technologies effectively.Ethical Considerations and Future Outlook

As AI becomes increasingly sophisticated, ethical considerations surrounding technological implementation have gained prominence. Conferences like MARCON 2025 are not just technological forums but platforms for discussing responsible innovation, addressing potential societal impacts, and establishing guidelines for ethical AI deployment in manufacturing environments. The future of manufacturing lies in creating intelligent, adaptive systems that balance technological efficiency with human creativity and ethical considerations. This holistic approach ensures that technological advancement serves broader societal goals while driving industrial progress.RELATED NEWS

Manufacturing

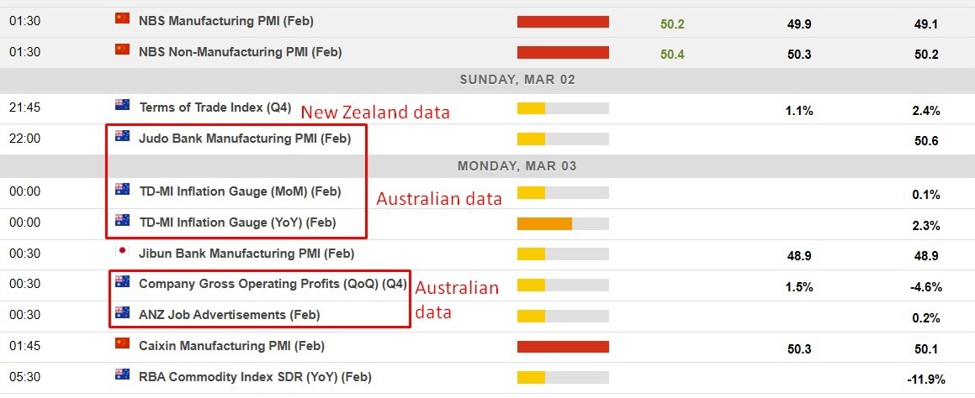

Manufacturing Pulse: China's Economic Heartbeat Revealed in Latest PMI Snapshot

2025-03-02 21:25:44

Manufacturing

Innovative Manufacturing Boost: Wood County Tech Center Secures Chemours Grant to Launch Cutting-Edge Program

2025-03-07 16:44:49

Manufacturing

Revolution in Pharma: How PHARMAP 2025 is Reshaping Manufacturing Frontiers

2025-02-24 13:28:09