3D Printing Revolution: Global Market Set to Explode by 2025, Experts Predict

Manufacturing

2025-02-17 13:37:48Content

Additive Manufacturing Market: A Technological Revolution Unfolding

The additive manufacturing industry is experiencing an extraordinary growth trajectory, marking a significant milestone in technological innovation. In 2023, the market size reached an impressive USD 20.2 Billion, setting the stage for remarkable expansion in the coming years.

Projections indicate a robust growth pattern, with the market expected to surge from USD 24.4 Billion in 2024 to a staggering USD 110.64 Billion by 2032. This represents a compelling Compound Annual Growth Rate (CAGR) of 20.8%, highlighting the sector's immense potential and transformative capabilities.

The rapid advancement of additive manufacturing technologies is driving unprecedented opportunities across multiple industries, including aerospace, automotive, healthcare, and manufacturing. As companies increasingly adopt 3D printing and advanced manufacturing techniques, the market is poised to revolutionize traditional production methods and unlock new frontiers of innovation.

Investors, technology enthusiasts, and industry leaders are closely watching this dynamic sector, recognizing its potential to reshape global manufacturing landscapes and drive sustainable, efficient production processes.

The Transformative Power of Additive Manufacturing: Revolutionizing Global Industries

In the rapidly evolving landscape of technological innovation, additive manufacturing stands as a beacon of transformative potential, reshaping how industries conceptualize, design, and produce complex components across multiple sectors. This groundbreaking technology represents more than just a manufacturing process—it's a paradigm shift that promises to redefine production methodologies, economic strategies, and technological capabilities on a global scale.Unleashing the Future: How 3D Printing is Reshaping Manufacturing Dynamics

The Economic Landscape of Additive Manufacturing

The global additive manufacturing ecosystem is experiencing an unprecedented trajectory of growth and innovation. Market projections indicate a remarkable expansion from approximately $20.2 billion in 2023 to an anticipated $110.64 billion by 2032, representing a compelling compound annual growth rate of 20.8%. This exponential growth reflects not merely a technological trend, but a fundamental restructuring of manufacturing paradigms across diverse industrial domains. The economic implications of this technological revolution extend far beyond traditional manufacturing boundaries. Companies are discovering unprecedented opportunities to optimize production processes, reduce material waste, and create intricate designs that were previously impossible or prohibitively expensive. The convergence of advanced materials, sophisticated software, and precision engineering is driving this transformative momentum.Technological Innovations Driving Additive Manufacturing

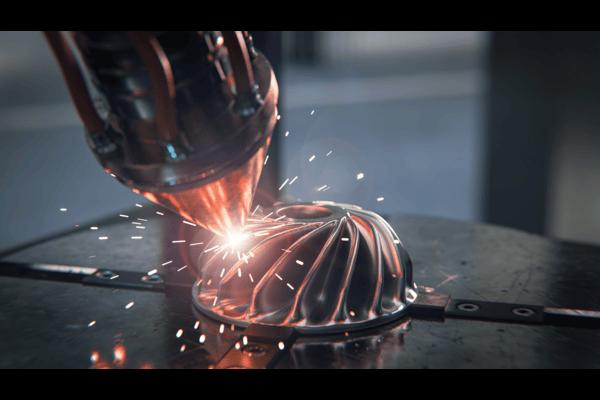

Cutting-edge developments in additive manufacturing are pushing the boundaries of what's technologically feasible. Advanced 3D printing technologies now enable the creation of complex geometries with microscopic precision, utilizing materials ranging from advanced polymers to metallic alloys and ceramic composites. These innovations are not just incremental improvements but represent quantum leaps in manufacturing capabilities. Engineers and researchers are continuously expanding the potential applications, developing techniques that allow for multi-material printing, enhanced structural integrity, and unprecedented design flexibility. The ability to produce lightweight, high-performance components with minimal material waste is revolutionizing industries from aerospace and automotive to medical devices and consumer electronics.Sector-Specific Transformations

Different industrial sectors are experiencing unique metamorphoses through additive manufacturing technologies. In aerospace, complex engine components can now be printed with intricate internal structures that optimize performance and reduce weight. The medical field is witnessing groundbreaking developments in personalized prosthetics, custom implants, and even bioprinting of living tissues. Automotive manufacturers are leveraging these technologies to prototype rapidly, reduce production costs, and create lightweight, high-performance parts. The construction industry is exploring large-scale 3D printing techniques that could potentially revolutionize architectural design and infrastructure development, offering more sustainable and cost-effective building methods.Sustainability and Environmental Considerations

Additive manufacturing emerges as a pivotal technology in addressing global sustainability challenges. By enabling precise material usage, reducing waste, and facilitating localized production, these technologies contribute significantly to reducing carbon footprints and promoting circular economy principles. The ability to produce components on-demand and closer to the point of use minimizes transportation costs and associated environmental impacts. Moreover, the potential for recycling and reusing materials in 3D printing processes presents an innovative approach to resource management and sustainable industrial practices.Future Outlook and Challenges

While the potential of additive manufacturing is immense, the path forward involves overcoming significant technological, economic, and regulatory challenges. Standardization of processes, development of advanced materials, and integration with existing manufacturing ecosystems remain critical focus areas for continued innovation. The next decade will likely witness unprecedented convergence of artificial intelligence, machine learning, and additive manufacturing, creating intelligent, adaptive production systems that can dynamically respond to complex design requirements and market demands.RELATED NEWS

Chip Giant's Big Move: Amundi Doubles Down on Taiwan Semiconductor with Massive Stock Purchase