Dental Tech Revolution: Axtra3D and Oqcam Forge Powerful Alliance to Transform 3D Printing Workflows

Manufacturing

2025-02-18 13:00:00Content

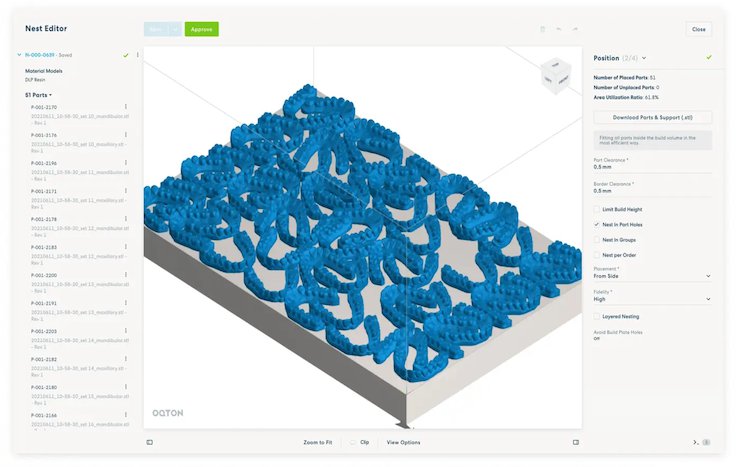

Oqcam and Axtra3D are revolutionizing the 3D printing workflow by combining cutting-edge artificial intelligence with advanced stereolithography (SLA) technology. Their collaborative solution aims to streamline the build preparation process, dramatically reducing manual intervention and increasing overall efficiency.

By leveraging Oqcam's intelligent AI-driven automated nesting capabilities, manufacturers can now optimize part placement and orientation with unprecedented precision. This innovative integration promises to significantly cut down setup time, allowing businesses to accelerate their production cycles and minimize human error.

The partnership represents a significant leap forward in additive manufacturing, demonstrating how artificial intelligence can transform traditional manufacturing processes. Engineers and production managers can now rely on smart algorithms to handle complex build preparation tasks, freeing up valuable human resources for more strategic activities.

As 3D printing continues to evolve, collaborations like this highlight the potential of AI to enhance manufacturing productivity and precision, setting new standards for automated production workflows.

Revolutionary AI and 3D Printing Collaboration: Transforming Manufacturing Efficiency

In the rapidly evolving landscape of advanced manufacturing technologies, groundbreaking partnerships are reshaping how industries approach production processes. The convergence of artificial intelligence and sophisticated 3D printing technologies represents a pivotal moment in industrial innovation, promising unprecedented levels of automation and precision.Unleashing the Power of Intelligent Manufacturing Solutions

The Technological Synergy of AI and Advanced 3D Printing

The collaboration between Oqcam and Axtra3D marks a significant milestone in manufacturing technology. By integrating cutting-edge artificial intelligence with state-of-the-art stereolithography (SLA) 3D printing systems, these companies are pioneering a new era of automated production workflows. The core objective of this partnership revolves around dramatically reducing manual intervention and optimizing the build preparation process. Artificial intelligence algorithms developed by Oqcam are specifically designed to revolutionize the complex task of component nesting. Traditional manufacturing approaches often require extensive human input for arranging and positioning components, a time-consuming and error-prone process. The AI-driven solution promises to streamline these operations, enabling manufacturers to achieve unprecedented levels of efficiency and precision.Transforming Production Workflows Through Intelligent Automation

The implementation of AI-powered automated build preparation represents a quantum leap in manufacturing technology. By leveraging sophisticated machine learning algorithms, the system can intelligently analyze and optimize component placement, reducing setup times and minimizing material waste. This approach not only enhances productivity but also significantly reduces operational costs. Stereolithography (SLA) 3D printing technology, provided by Axtra3D, complements the AI capabilities by offering exceptional resolution and accuracy. The combination of intelligent software and advanced printing technology creates a holistic solution that addresses multiple challenges in modern manufacturing environments.Strategic Implications for Manufacturing Industries

This technological integration extends far beyond mere technical innovation. It represents a fundamental shift in how manufacturing processes are conceptualized and executed. Industries ranging from medical device production to aerospace engineering stand to benefit immensely from such intelligent automation solutions. The ability to reduce manual setup time while maintaining high precision opens up new possibilities for manufacturers. Companies can now allocate human resources more strategically, focusing on complex problem-solving and innovation rather than repetitive technical tasks. Moreover, the increased efficiency translates directly into competitive advantages in an increasingly demanding global market.Future Prospects and Technological Evolution

As artificial intelligence and 3D printing technologies continue to mature, collaborations like the one between Oqcam and Axtra3D are likely to become increasingly common. The potential for further optimization and innovation remains vast, with researchers and engineers constantly pushing the boundaries of what's possible. The partnership serves as a compelling case study of how interdisciplinary technological collaboration can drive meaningful industrial transformation. By breaking down traditional silos and fostering innovative approaches, companies can unlock new levels of manufacturing excellence.RELATED NEWS

Manufacturing

Investor Shift: M. Kulyk & Associates Trims Stakes in Tech Giant Taiwan Semiconductor

2025-03-09 11:38:16

Manufacturing

Breaking Barriers: How Forterra's Female Workforce is Revolutionizing Manufacturing

2025-03-10 23:53:23