Breaking: A3 Unveils Groundbreaking Safety Protocols for Industrial Robotics

Manufacturing

2025-02-18 14:36:33Content

Major Update Revamps Digital Security Guidelines After Decade-Long Wait

In a landmark move that signals a significant shift in digital security protocols, experts have unveiled a comprehensive revision of critical guidelines—the first substantial update since 2011. This long-overdue transformation reflects the dramatic technological landscape changes and emerging cybersecurity challenges of the past decade.

The updated framework addresses the rapidly evolving digital ecosystem, incorporating insights from recent cybersecurity incidents, technological advancements, and sophisticated threat landscapes. By reimagining security strategies, the new guidelines aim to provide organizations and individuals with more robust, adaptive protection mechanisms.

Key highlights of the revision include enhanced data protection strategies, more nuanced risk assessment protocols, and comprehensive recommendations for defending against increasingly complex cyber threats. The update represents a proactive approach to digital security, acknowledging that traditional defense models are no longer sufficient in today's interconnected world.

Cybersecurity professionals have welcomed the revision, noting that it provides much-needed clarity and direction in an increasingly complex digital environment. The guidelines are expected to become a critical reference point for organizations seeking to strengthen their digital resilience.

Robotic Revolution: Transforming Manufacturing in the Digital Age

In an era of unprecedented technological advancement, the manufacturing landscape is undergoing a radical metamorphosis. The integration of cutting-edge robotics is reshaping industrial processes, challenging traditional production paradigms, and ushering in a new epoch of technological innovation that promises to redefine how we conceptualize industrial productivity and efficiency.Unleashing the Power of Automation: A Technological Breakthrough That Will Transform Industries Forever

The Evolutionary Trajectory of Robotic Manufacturing

The journey of robotics in manufacturing represents a profound technological narrative that extends far beyond mere mechanical replacement. Modern robotic systems are sophisticated intelligent entities capable of complex decision-making, adaptive learning, and intricate task execution. These advanced machines are not simply tools but collaborative partners in the industrial ecosystem, integrating artificial intelligence, machine learning algorithms, and precision engineering to create unprecedented levels of operational excellence. Contemporary robotic platforms demonstrate remarkable versatility, seamlessly transitioning between intricate assembly processes, quality control mechanisms, and complex logistical operations. Their ability to operate with microscopic precision while maintaining consistent performance levels represents a quantum leap in manufacturing capabilities.Technological Innovations Driving Robotic Integration

Cutting-edge technological developments are propelling robotic systems into unprecedented realms of functionality. Advanced sensor technologies, coupled with sophisticated machine learning algorithms, enable robots to perceive and interact with their environments with human-like sophistication. Computer vision systems, neural network architectures, and real-time data processing capabilities transform these mechanical entities into intelligent, adaptive workforce members. The convergence of artificial intelligence, cloud computing, and advanced robotics creates a synergistic ecosystem where machines can learn, adapt, and optimize their performance continuously. This dynamic interaction between human expertise and robotic precision represents the future of industrial production, promising exponential gains in efficiency, accuracy, and innovation.Economic and Workforce Implications of Robotic Transformation

The widespread adoption of robotic technologies carries profound economic and societal implications. While concerns about workforce displacement persist, emerging evidence suggests a more nuanced narrative of technological augmentation rather than wholesale replacement. Robotic systems are increasingly viewed as collaborative tools that enhance human capabilities, creating new job categories and driving economic productivity. Organizations implementing advanced robotic solutions are experiencing significant competitive advantages, including reduced operational costs, enhanced product quality, and accelerated production cycles. The economic calculus of robotic investment is shifting, with increasingly sophisticated systems offering compelling return-on-investment propositions for forward-thinking enterprises.Ethical and Philosophical Considerations in Robotic Manufacturing

The integration of advanced robotic systems raises complex ethical and philosophical questions about the nature of work, human-machine interaction, and technological progress. As these intelligent systems become more sophisticated, society must grapple with fundamental questions about autonomy, decision-making capabilities, and the evolving relationship between human creativity and mechanical precision. Responsible technological implementation requires a holistic approach that balances technological innovation with ethical considerations, ensuring that robotic advancements serve human interests and contribute positively to societal progress. This demands ongoing dialogue, interdisciplinary collaboration, and a nuanced understanding of the transformative potential of robotic technologies.RELATED NEWS

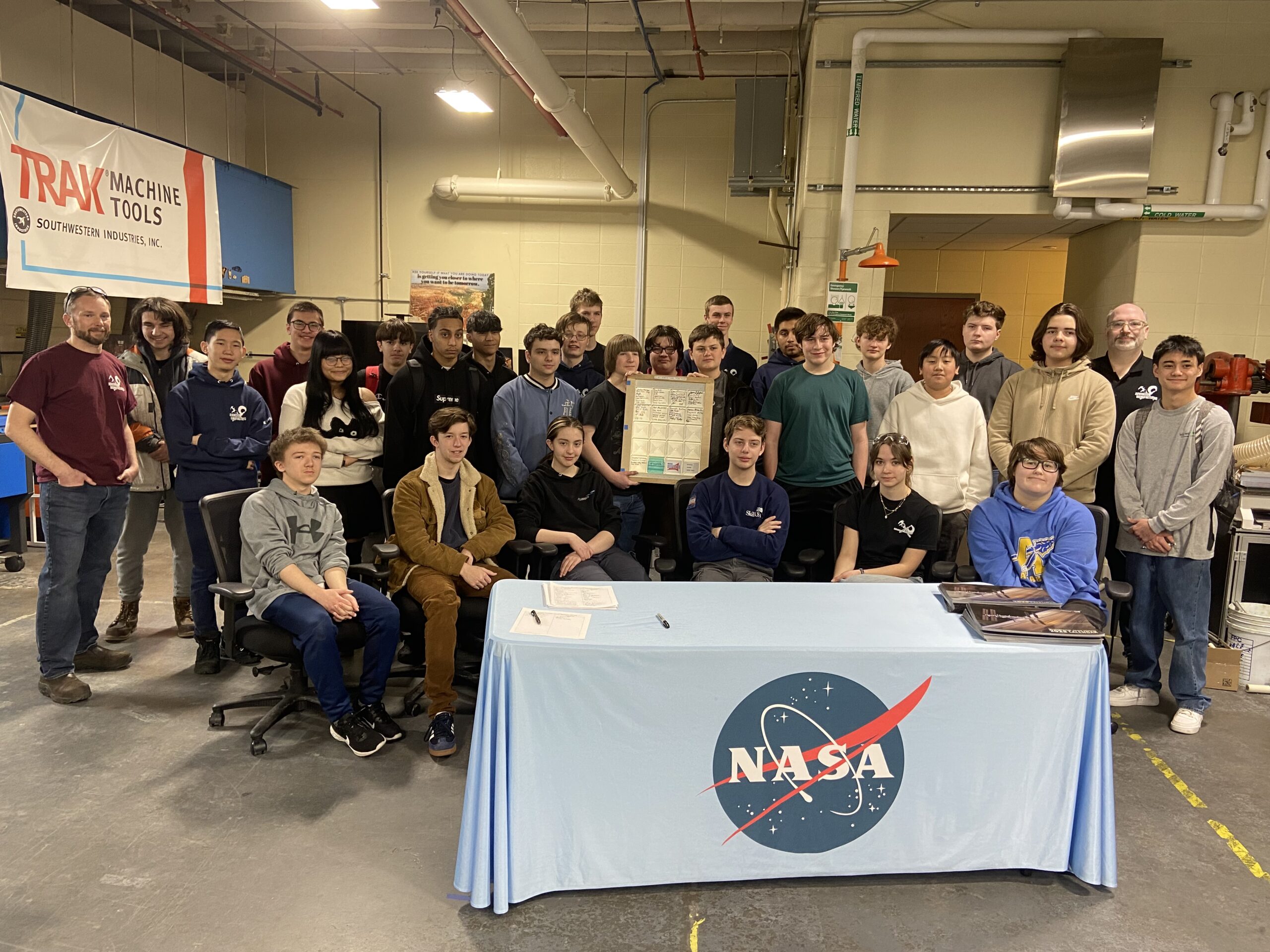

Space-Bound Scholars: Local Students' Locker Set to Orbit Earth on NASA Mission

Breaking: TSMC Unveils Cutting-Edge 3nm Chip for OpenAI, Signaling New AI Hardware Revolution