Fashion Tech Revolution: MMU Unveils Cutting-Edge Collaborative Robot Manufacturing Lab in UK First

Manufacturing

2025-02-19 11:53:49Content

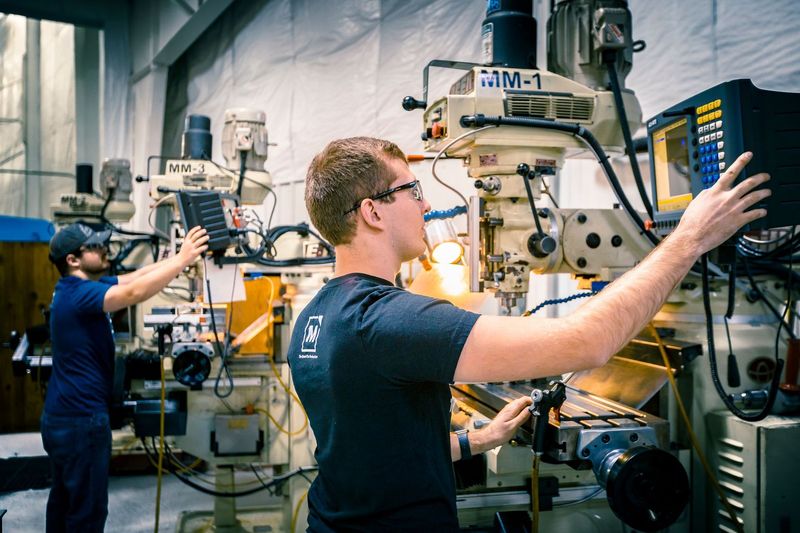

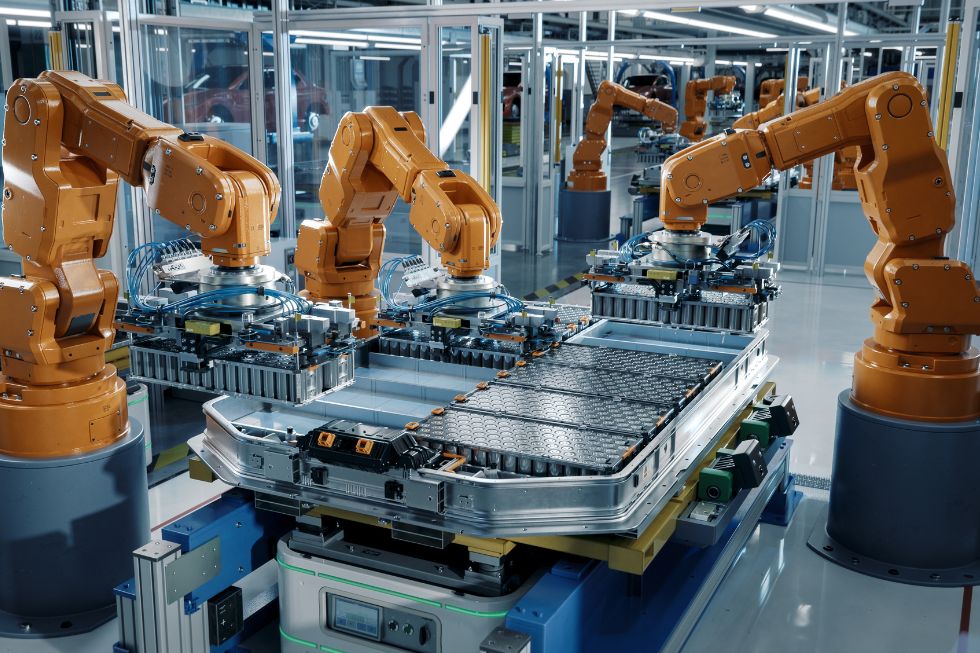

The Manchester Fashion Institute has taken a groundbreaking step in textile innovation by launching its cutting-edge Robotics Living Lab (RoLL). This state-of-the-art fashion manufacturing laboratory represents a significant leap forward in integrating collaborative robotics into the fashion design and production process.

The new facility will leverage collaborative robots, or "cobots," to revolutionize how fashion manufacturing operates. By combining advanced robotics technology with creative design principles, the institute aims to transform traditional manufacturing methods and set new industry standards.

RoLL promises to bridge the gap between technological innovation and fashion design, offering students and researchers an unprecedented opportunity to explore the intersection of robotics and textile production. This pioneering initiative underscores Manchester's commitment to pushing the boundaries of fashion technology and preparing the next generation of industry professionals for a more automated and efficient future.

Revolutionary Robotics: Manchester's Fashion Institute Pioneers Collaborative Manufacturing Transformation

In the rapidly evolving landscape of fashion technology, educational institutions are increasingly becoming crucibles of innovation, pushing the boundaries of traditional manufacturing paradigms. The Manchester Fashion Institute stands at the forefront of this technological revolution, demonstrating an unprecedented commitment to integrating cutting-edge robotics into fashion production methodologies.Transforming Fashion Manufacturing Through Intelligent Automation

The Rise of Collaborative Robotics in Textile Production

The emergence of collaborative robots, or cobots, represents a groundbreaking shift in manufacturing dynamics. Unlike traditional industrial robots that operate in isolation, these intelligent machines are designed to work seamlessly alongside human workers, enhancing productivity while maintaining a human-centric approach. In the context of fashion manufacturing, cobots offer unprecedented precision, adaptability, and efficiency. Cobots are engineered with advanced sensor technologies and machine learning algorithms that enable them to understand and respond to human movements in real-time. This symbiotic relationship between human creativity and robotic precision promises to revolutionize textile production, reducing manual labor while simultaneously improving quality control and production speed.Manchester Fashion Institute's Robotics Living Lab: A Technological Milestone

The establishment of the Robotics Living Lab (RoLL) marks a significant milestone in fashion education and technological innovation. This state-of-the-art facility represents more than just a laboratory; it's a visionary ecosystem where cutting-edge robotics converge with fashion design and manufacturing principles. By integrating cobots into their educational framework, the Manchester Fashion Institute is preparing the next generation of fashion professionals to navigate an increasingly automated industrial landscape. Students will gain hands-on experience with advanced robotic systems, learning to program, manage, and collaborate with these intelligent machines.Technological Implications for Future Fashion Manufacturing

The implementation of collaborative robotics extends far beyond mere technological novelty. It signifies a profound transformation in how fashion products are conceptualized, designed, and manufactured. Cobots can perform intricate tasks with microscopic precision, from pattern cutting to complex stitching techniques that would challenge human dexterity. Moreover, these robotic systems offer significant advantages in terms of sustainability. By optimizing material usage, reducing waste, and improving production efficiency, cobots contribute to more environmentally conscious manufacturing processes. The Manchester Fashion Institute's initiative represents a holistic approach to technological innovation that considers both industrial efficiency and ecological responsibility.Training the Next Generation of Technological Innovators

The Robotics Living Lab serves as a critical educational platform, bridging the gap between theoretical knowledge and practical application. Students will not only learn about robotic technologies but will actively engage with them, developing skills that are increasingly valuable in a rapidly digitalizing global economy. By exposing fashion students to collaborative robotics, the institute is cultivating a generation of professionals who understand the intricate relationship between human creativity and technological capability. This approach ensures that future fashion professionals are not just consumers of technology but active creators and innovators.Global Implications and Industry Perspectives

The Manchester Fashion Institute's initiative is more than a localized experiment; it represents a global trend towards intelligent, collaborative manufacturing systems. As industries worldwide seek to optimize production processes, collaborative robotics emerge as a transformative solution that balances human creativity with technological precision. International fashion brands and manufacturers are closely observing such educational innovations, recognizing their potential to reshape traditional manufacturing paradigms. The Robotics Living Lab stands as a beacon of progressive thinking, demonstrating how educational institutions can drive technological advancement and industry transformation.RELATED NEWS

Manufacturing

Powering the AI Revolution: Flex Expands Texas Footprint with Cutting-Edge Dallas Plant

2025-02-20 22:07:07

Manufacturing

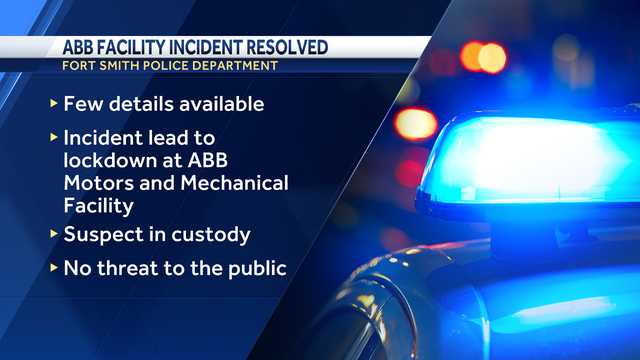

Breaking: Workplace Tension Ends as ABB Motors Facility Lockdown Comes to Peaceful Conclusion

2025-02-28 02:23:00

Manufacturing

Electric Vehicles: Why Trade Battles Can't Rescue U.S. Manufacturing's Deeper Crisis

2025-02-25 13:02:07