Sweet Success: Charms Blows Up Tennessee Operations with Nearly $100M Expansion

Manufacturing

2025-02-19 20:59:50Content

For nearly five decades, this Tennessee manufacturing facility has been a sweet cornerstone of American candy production. Since 1973, the plant has been delighting candy lovers across the nation, specializing in the iconic Blow Pops that have become a beloved treat for generations. Nestled in the heart of Tennessee, this facility has perfected the art of creating delectable confections, transforming simple ingredients into colorful, flavor-packed candies that have become a staple in convenience stores, movie theaters, and candy aisles nationwide.

The facility's long-standing commitment to quality and innovation has made it a key player in the confectionery industry, continuing to produce not just Blow Pops, but a wide range of sweet treats that bring joy to candy enthusiasts of all ages. From its humble beginnings in 1973 to its current status as a candy manufacturing powerhouse, this Tennessee plant represents a delicious piece of American culinary history.

Sweet Success: The Blow Pop Empire's Expansion in Tennessee's Manufacturing Landscape

In the heart of Tennessee's industrial corridor, a remarkable story of confectionery innovation and economic resilience unfolds, tracing the remarkable journey of a candy manufacturing facility that has become a cornerstone of regional production and sweet memories for generations.Where Sugary Dreams Meet Industrial Precision

The Historical Roots of Confectionery Manufacturing

The Tennessee manufacturing facility represents far more than a mere production site; it embodies a rich tapestry of industrial heritage and entrepreneurial spirit. Established in 1973, this facility has witnessed transformative changes in the confectionery landscape, adapting and evolving through decades of technological advancements and shifting consumer preferences. Nestled within the state's robust manufacturing ecosystem, the facility has consistently demonstrated remarkable resilience. Its ability to maintain production excellence while embracing innovation has positioned it as a critical player in the national candy manufacturing sector. The facility's longevity speaks volumes about its operational efficiency and strategic adaptability.Technological Evolution in Candy Production

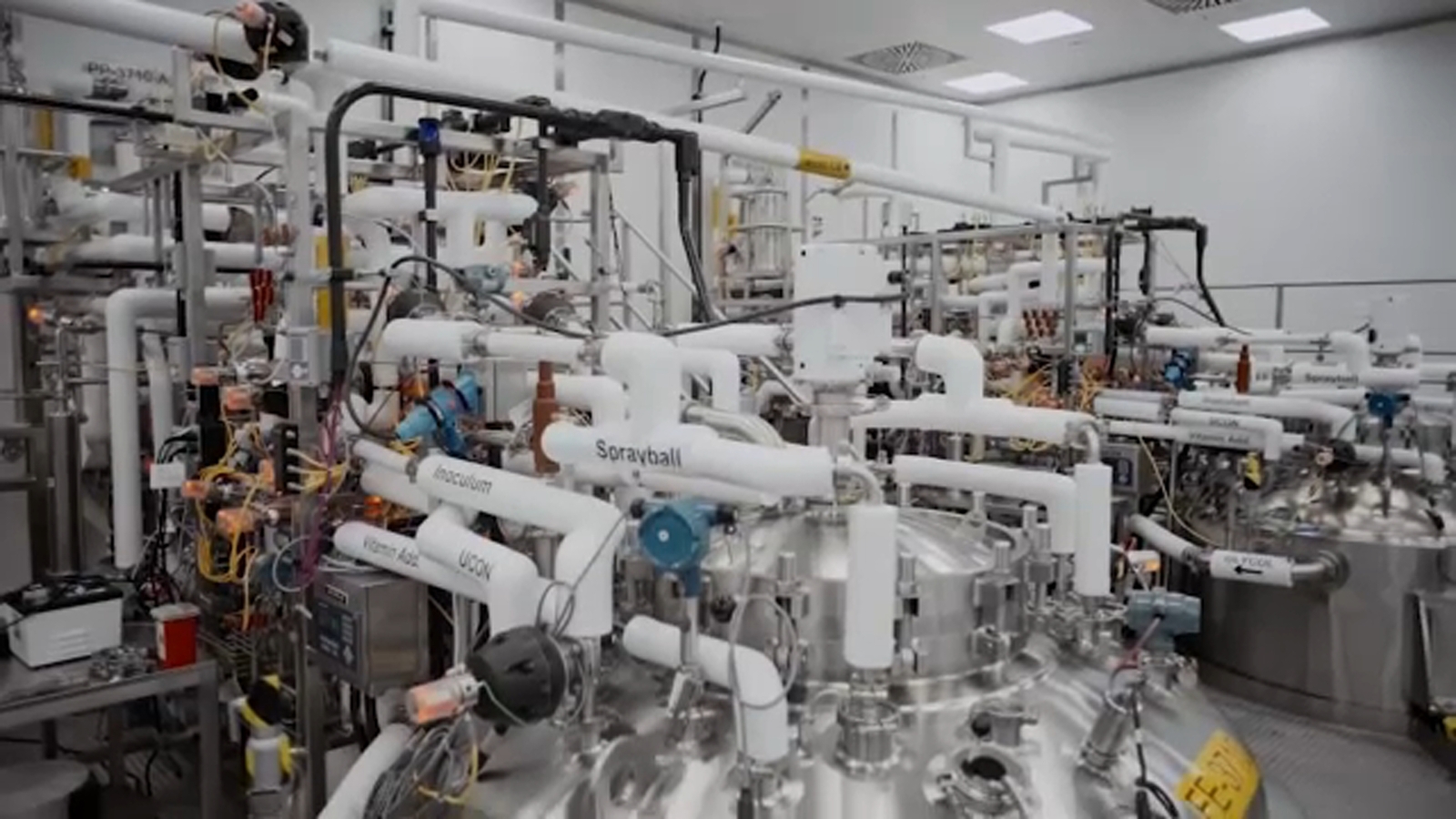

Modern candy manufacturing represents a sophisticated intersection of culinary art and cutting-edge engineering. The Tennessee facility exemplifies this convergence, utilizing state-of-the-art equipment and precision manufacturing techniques to produce iconic treats like Blow Pops with unparalleled consistency and quality. Advanced automation systems, coupled with rigorous quality control protocols, ensure that each candy meets exacting standards. Sophisticated machinery capable of intricate sugar work, precise molding, and rapid packaging has revolutionized how confectionery products are conceptualized and produced.Economic Impact and Regional Development

Beyond its primary function of candy production, the facility serves as a significant economic engine for the local community. By providing stable employment, supporting local supply chains, and contributing to regional economic vitality, it represents a microcosm of American industrial resilience. The facility's continued expansion reflects broader trends in manufacturing, demonstrating how strategic investments in infrastructure and workforce development can create sustainable economic opportunities. Its presence underscores Tennessee's reputation as a hub for diverse and innovative manufacturing capabilities.Sustainability and Future Perspectives

Contemporary manufacturing increasingly demands environmental consciousness and sustainable practices. The Tennessee facility has been proactively integrating eco-friendly technologies, exploring waste reduction strategies, and implementing energy-efficient production methodologies. Forward-looking strategies include exploring alternative packaging materials, optimizing energy consumption, and developing production processes that minimize environmental impact. These initiatives not only reduce operational costs but also align with growing consumer expectations for responsible manufacturing.Cultural Significance of Iconic Confectionery

Blow Pops represent more than a mere candy; they are cultural artifacts that have accompanied generations through childhood memories and nostalgic moments. The Tennessee facility plays a crucial role in maintaining the authenticity and quality of these beloved treats. Each Blow Pop carries with it a narrative of craftsmanship, representing countless hours of engineering, culinary expertise, and passionate dedication to creating moments of pure, unadulterated joy. The facility's commitment to maintaining product excellence ensures that these sweet experiences continue to be shared and cherished.RELATED NEWS

Manufacturing

Wheels of Change: Fetterman's Bold Bipartisan Push to Revive American Bus Industry

2025-02-24 21:00:00

Manufacturing

Merck Unveils Cutting-Edge Vaccine Hub in North Durham, Boosting Regional Biotech Landscape

2025-03-11 16:52:00

Manufacturing

Lifeline in Limbo: How USAID Turmoil Threatens Critical Infant Survival Product

2025-02-28 23:42:35