Manufacturing Revolution: How Bevis and Timmons Are Reshaping America's Industrial Landscape

Manufacturing

2025-02-21 18:58:44Content

Manufacturing's Future: Seizing Opportunities in a Transformative Era

The manufacturing landscape is undergoing a profound transformation, driven by technological innovation, global economic shifts, and changing market dynamics. Companies that act decisively now will be best positioned to thrive in this rapidly evolving environment.

Embracing Digital Transformation

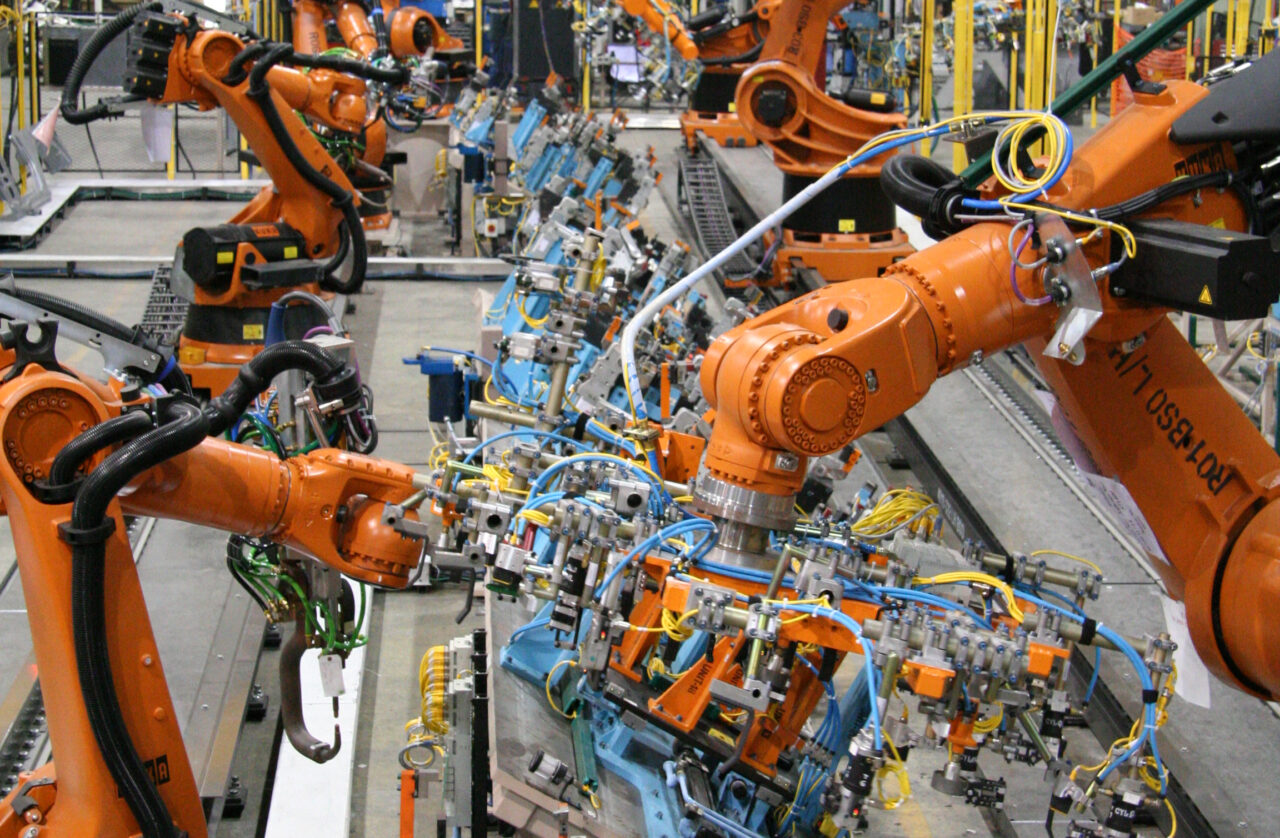

The key to success lies in embracing cutting-edge technologies like artificial intelligence, advanced robotics, and the Internet of Things (IoT). These innovations are not just buzzwords, but powerful tools that can dramatically enhance productivity, efficiency, and competitiveness.

Strategic Investments and Adaptability

Forward-thinking manufacturers must be willing to invest strategically in new technologies and skills. This means not only upgrading equipment but also developing a workforce capable of leveraging these advanced tools. Continuous learning and adaptability are no longer optional—they're essential for survival.

Sustainable and Resilient Supply Chains

The recent global disruptions have highlighted the critical importance of building robust, flexible supply chains. Manufacturers must diversify their supplier networks, embrace digital supply chain management, and develop contingency strategies to mitigate potential risks.

The Time to Act is Now

The manufacturing sector stands at a critical crossroads. Those who hesitate risk being left behind, while proactive companies can transform challenges into unprecedented opportunities. By acting decisively, investing wisely, and maintaining a forward-looking perspective, manufacturers can shape their own successful future.

Revolutionizing Manufacturing: The Next Frontier of Industrial Innovation

In an era of unprecedented technological transformation, the manufacturing landscape stands at a critical crossroads. The convergence of advanced technologies, global economic shifts, and emerging workforce dynamics is reshaping how industries conceptualize production, efficiency, and competitive advantage.Transforming Industry: Where Innovation Meets Opportunity

The Digital Manufacturing Revolution

The manufacturing sector is experiencing a profound metamorphosis driven by cutting-edge technologies. Artificial intelligence, machine learning, and advanced robotics are no longer futuristic concepts but immediate operational realities. Companies that embrace these technological paradigms are discovering unprecedented opportunities for optimization, precision, and scalability. Intelligent manufacturing systems now integrate complex algorithms that can predict maintenance requirements, optimize production workflows, and dramatically reduce operational inefficiencies. By leveraging real-time data analytics, manufacturers can create adaptive production environments that respond dynamically to market demands and internal performance metrics.Sustainable Manufacturing Strategies

Environmental consciousness has transitioned from a peripheral consideration to a core strategic imperative. Modern manufacturers are reimagining production processes through a sustainability lens, implementing circular economy principles that minimize waste, reduce carbon footprints, and create more resilient supply chains. Innovative materials, renewable energy integration, and advanced recycling technologies are enabling companies to achieve unprecedented levels of environmental performance. These strategies are not just ethical imperatives but increasingly become competitive differentiators in a global marketplace that demands responsible industrial practices.Workforce Transformation and Skill Development

The manufacturing workforce is undergoing a radical reinvention. Traditional manual labor roles are evolving into sophisticated technological positions requiring advanced digital skills, critical thinking, and adaptive problem-solving capabilities. Educational institutions and corporations are collaborating to develop comprehensive reskilling programs that bridge technological gaps and prepare workers for the next generation of industrial challenges. Emerging training models incorporate immersive technologies like virtual reality and augmented reality, allowing workers to gain complex skills through interactive, risk-free learning environments. These approaches accelerate skill acquisition and create more engaging, personalized learning experiences.Global Supply Chain Resilience

Recent global disruptions have exposed critical vulnerabilities in traditional supply chain models. Manufacturers are now developing more sophisticated, flexible, and technologically integrated supply networks that can rapidly adapt to geopolitical, economic, and environmental challenges. Advanced predictive modeling, blockchain technologies, and artificial intelligence are enabling unprecedented levels of supply chain transparency, risk management, and strategic agility. Companies are moving beyond traditional linear supply models towards more interconnected, responsive ecosystems that can quickly reconfigure in response to dynamic global conditions.Technological Investment and Economic Strategy

Strategic technological investment has become a fundamental driver of manufacturing competitiveness. Organizations are allocating significant resources towards research and development, recognizing that continuous innovation is not optional but essential for survival in a rapidly evolving global marketplace. Governments and private sector entities are increasingly collaborating to create innovation ecosystems that support technological research, startup development, and industrial transformation. These partnerships are crucial in maintaining national economic competitiveness and driving forward-thinking industrial strategies.RELATED NEWS

Manufacturing Boom: NXG Truck Bodies Revs Up $20M Plant in Mount Pleasant

Powering America's Future: Clarios Unleashes $6 Billion Battery Manufacturing Boom