Pharma Giant's $27B Bet: Eli Lilly Fortifies U.S. Drug Production Ahead of Potential Trade Tensions

Manufacturing

2025-02-26 15:48:26Content

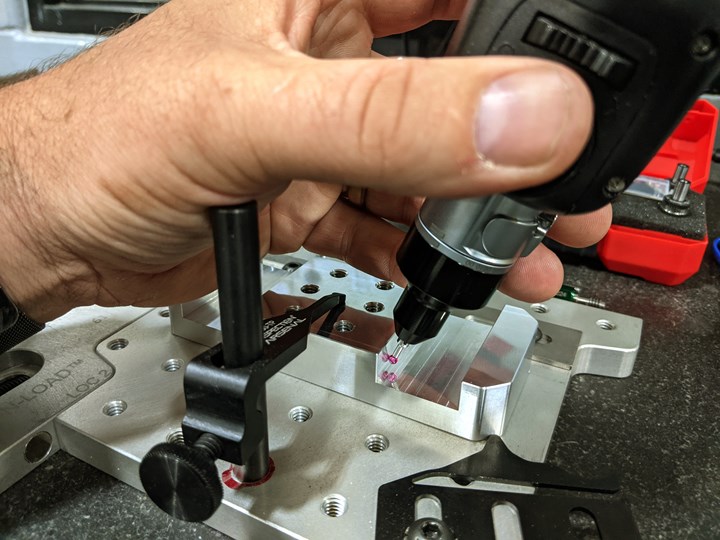

Eli Lilly was already making strategic moves to bring manufacturing closer to home, with a robust commitment to expanding domestic production capabilities. The pharmaceutical giant has been actively investing in onshore manufacturing infrastructure, particularly to ramp up production for its breakthrough medications Zepbound and Mounjaro. This proactive approach reflects the company's forward-thinking strategy to strengthen its domestic manufacturing footprint and reduce reliance on international supply chains.

By localizing production, Lilly aims to enhance supply chain resilience, reduce potential logistical disruptions, and demonstrate a commitment to supporting the domestic manufacturing ecosystem. The significant investments in onshore production facilities not only underscore the company's confidence in these groundbreaking treatments but also signal a broader trend of pharmaceutical companies prioritizing local manufacturing capabilities.

Pharmaceutical Manufacturing Revolution: Lilly's Strategic Onshoring Transformation

In the rapidly evolving landscape of pharmaceutical production, companies are increasingly reimagining their manufacturing strategies to enhance resilience, efficiency, and domestic capabilities. Eli Lilly, a global pharmaceutical giant, stands at the forefront of this transformative movement, signaling a profound shift in how critical medications are developed and produced.Reshaping the Future of Drug Manufacturing with Bold Strategic Investments

The Emerging Paradigm of Domestic Pharmaceutical Production

The pharmaceutical industry is experiencing a seismic transformation, driven by complex geopolitical dynamics and strategic imperatives. Eli Lilly's aggressive approach to onshoring manufacturing represents more than a mere operational adjustment—it's a comprehensive reimagining of pharmaceutical supply chain architecture. By localizing production capabilities, the company is not just mitigating global supply chain risks but also positioning itself as an innovative leader in a rapidly changing global marketplace. Pharmaceutical manufacturers are increasingly recognizing the strategic advantages of domestic production. This shift goes beyond traditional cost considerations, encompassing broader concerns about geopolitical stability, technological sovereignty, and rapid response capabilities. Lilly's investments signal a nuanced understanding that manufacturing is no longer just about production efficiency, but about creating robust, adaptable ecosystems capable of responding to unprecedented global challenges.Strategic Investments in Critical Medication Production

The focus on Zepbound and Mounjaro represents a calculated strategic move that transcends conventional pharmaceutical development approaches. These medications, which have demonstrated significant market potential, are now receiving unprecedented manufacturing attention. By dramatically expanding domestic production capacity, Lilly is not merely scaling operations but fundamentally reimagining its technological and operational infrastructure. This investment strategy reflects a sophisticated understanding of market dynamics. By localizing production, the company can achieve greater control over quality, reduce logistical complexities, and respond more rapidly to market demands. The approach also allows for more agile research and development processes, enabling faster iterations and more responsive product development cycles.Technological Innovation and Manufacturing Resilience

Lilly's onshoring initiative is intrinsically linked to technological innovation. Modern pharmaceutical manufacturing is no longer about simple production but about creating intelligent, data-driven manufacturing ecosystems. Advanced technologies like artificial intelligence, machine learning, and precision robotics are being integrated into production processes, transforming traditional manufacturing models. The company's commitment to domestic production also carries significant economic implications. By investing in local manufacturing capabilities, Lilly is contributing to job creation, technological development, and national economic resilience. This approach represents a holistic view of corporate responsibility that extends far beyond traditional profit-driven models.Global Context and Future Implications

The pharmaceutical industry's ongoing transformation reflects broader global trends toward localization and strategic self-sufficiency. Lilly's approach serves as a potential blueprint for other organizations seeking to navigate increasingly complex global economic landscapes. By prioritizing domestic manufacturing capabilities, the company is not just protecting its operational interests but also contributing to a more robust and adaptable pharmaceutical ecosystem. As geopolitical uncertainties continue to challenge global supply chains, strategies like Lilly's onshoring initiative will likely become increasingly prevalent. The ability to rapidly adapt, localize, and innovate will separate industry leaders from followers in the coming decades.RELATED NEWS

Manufacturing

Defense Dollars Boost: $8.5M Supercharges Upper Peninsula Manufacturing Powerhouse

2025-02-13 20:41:45

Manufacturing

Factory Floors Falter: Italy's Industrial Heartbeat Struggles to Recover

2025-03-03 10:39:53

Manufacturing

From Workshop to Workforce: How Manufacturing Students Are Revolutionizing Certification Standards

2025-02-17 00:00:00