From Prototype to Production: How Digital Threads Are Revolutionizing 3D Printing

Manufacturing

2025-03-03 10:00:00Content

In the rapidly evolving world of advanced manufacturing, 3D printing stands at the forefront of technological innovation. Olivier Diegerick, a leading expert in Additive Manufacturing Portfolio Development at Siemens Digital Industries Software, offers a compelling insight into how the digital thread can revolutionize industrial-scale 3D printing.

The digital thread represents a transformative approach that seamlessly connects design, production, and performance data across the entire manufacturing lifecycle. By creating an integrated, end-to-end digital ecosystem, manufacturers can unlock unprecedented potential in 3D printing technologies.

Diegerick explains that the digital thread enables unprecedented levels of precision, efficiency, and innovation. It allows engineers and designers to track every aspect of the manufacturing process, from initial concept to final product, ensuring optimal performance and quality control.

Key benefits of implementing the digital thread in 3D printing include:

• Enhanced design optimization

• Real-time performance monitoring

• Reduced time-to-market

• Improved product customization

• Minimized production errors

As industries continue to embrace advanced manufacturing techniques, the digital thread emerges as a critical strategy for companies seeking to maximize the transformative potential of 3D printing technologies.

Revolutionizing Manufacturing: The Digital Thread's Transformative Power in 3D Printing

In the rapidly evolving landscape of advanced manufacturing, technological innovations are reshaping how industries conceptualize, design, and produce complex components. The convergence of digital technologies and additive manufacturing represents a paradigm shift that promises to unlock unprecedented levels of efficiency, customization, and precision across multiple industrial sectors.Unleashing the Future: How Digital Transformation is Redefining Industrial Production

The Digital Thread: A Technological Breakthrough

The digital thread emerges as a revolutionary concept that seamlessly integrates design, production, and operational processes through advanced technological platforms. Unlike traditional manufacturing methodologies, this approach enables real-time data synchronization and intelligent decision-making across complex industrial ecosystems. Manufacturers can now track every aspect of a product's lifecycle with unprecedented granularity, transforming how engineering teams conceptualize and execute sophisticated manufacturing strategies. By creating a comprehensive digital representation of physical assets, organizations can simulate, predict, and optimize manufacturing processes before actual production begins. This approach dramatically reduces development cycles, minimizes potential errors, and significantly enhances overall operational efficiency.Additive Manufacturing's Technological Evolution

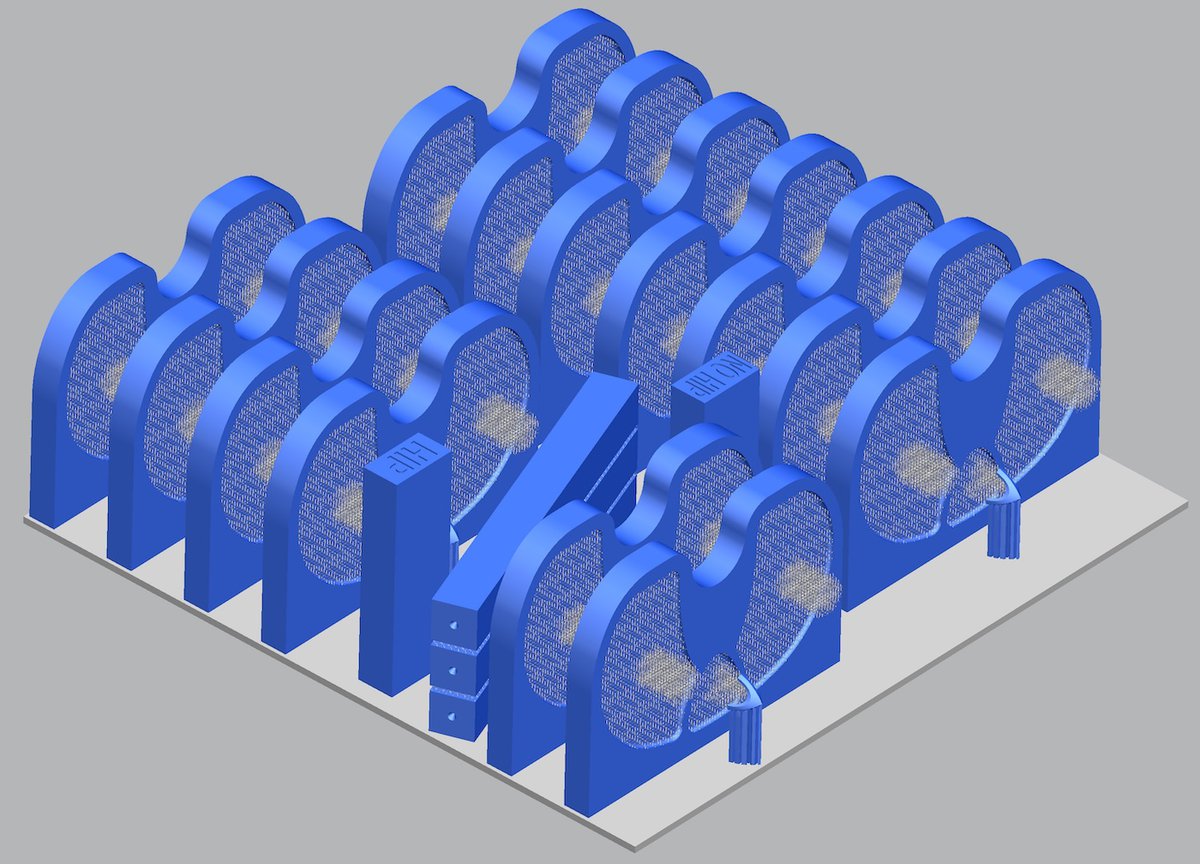

Three-dimensional printing has transcended its initial prototyping roots, emerging as a critical manufacturing technology capable of producing intricate, high-performance components across diverse industries. From aerospace and medical devices to automotive and industrial machinery, additive manufacturing represents a quantum leap in production capabilities. The integration of advanced software platforms enables engineers to design increasingly complex geometries that were previously impossible or economically unfeasible. Sophisticated algorithms now allow for topology optimization, material performance prediction, and structural integrity analysis, pushing the boundaries of what can be manufactured.Software's Transformative Role in Industrial Innovation

Digital engineering platforms play a pivotal role in translating conceptual designs into manufacturable solutions. Advanced simulation tools enable engineers to model complex scenarios, predict performance characteristics, and validate design parameters before physical production commences. Siemens Digital Industries Software exemplifies this technological convergence, providing comprehensive solutions that bridge conceptual design, engineering simulation, and manufacturing execution. By creating an integrated digital ecosystem, manufacturers can dramatically reduce time-to-market, minimize development costs, and enhance product performance.Challenges and Opportunities in Advanced Manufacturing

While digital thread technologies offer immense potential, their successful implementation requires significant organizational transformation. Companies must invest in workforce training, technological infrastructure, and cultural adaptability to fully leverage these advanced manufacturing paradigms. The convergence of artificial intelligence, machine learning, and additive manufacturing promises to unlock new frontiers of industrial innovation. Organizations that successfully navigate this technological landscape will gain substantial competitive advantages, enabling them to respond more dynamically to market demands and technological disruptions.Global Manufacturing Implications

The digital thread's impact extends far beyond individual manufacturing processes, representing a fundamental reimagining of how industrial production can be conceptualized, executed, and optimized. By creating interconnected, intelligent manufacturing ecosystems, organizations can achieve unprecedented levels of efficiency, sustainability, and innovation. As global supply chains become increasingly complex and competitive, the ability to leverage advanced digital technologies will distinguish industry leaders from followers. The digital thread offers a comprehensive approach to managing this complexity, providing manufacturers with powerful tools to navigate an increasingly dynamic global marketplace.RELATED NEWS

Manufacturing

Apple's Massive U.S. Bet: Inside the Tech Giant's Groundbreaking Investment

2025-02-24 19:21:00

Manufacturing

Behind Apple's Massive $500B Bet: Reshaping American Manufacturing

2025-02-25 00:08:05

Manufacturing

Engineering Software Giant nTop Expands Capabilities with Cloudfluid Acquisition, Revolutionizing Design-to-Manufacturing Workflows

2025-02-20 06:32:00