Factory Pulse: Manufacturers Caught Between Rising Costs and Investment Crossroads

Manufacturing

2025-03-07 11:00:53Content

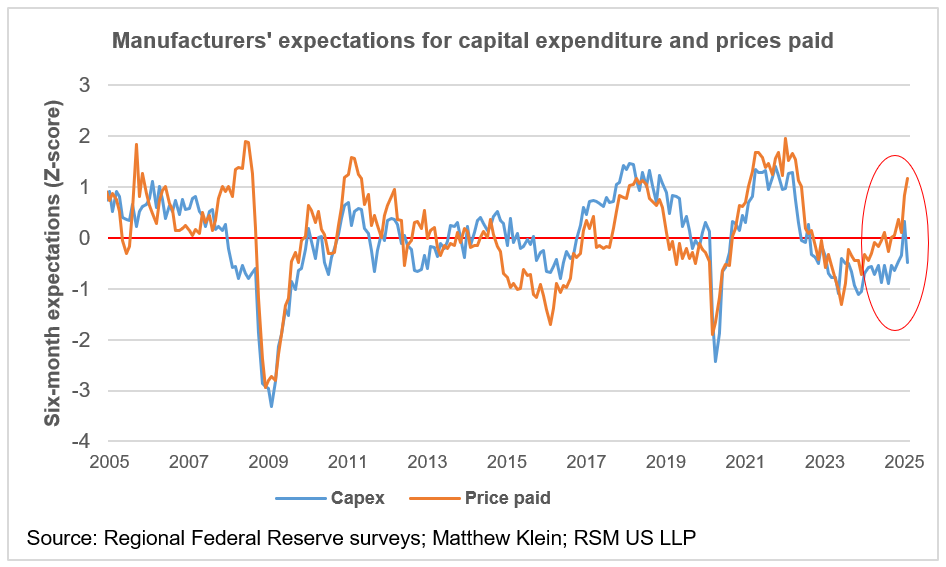

The latest RSM US Manufacturing Outlook Index continues to signal challenging conditions in the manufacturing sector, pointing to subdued production levels and economic headwinds. Our analysis reveals that manufacturing activity remains below typical performance benchmarks, reflecting ongoing economic uncertainties and potential structural challenges facing industrial producers.

Despite persistent market pressures, manufacturers are navigating a complex landscape of supply chain disruptions, fluctuating demand, and evolving economic indicators. The index suggests that the sector is experiencing a period of cautious adaptation, with businesses carefully managing resources and strategic investments in response to current market dynamics.

Stakeholders and industry observers should closely monitor these trends, as the manufacturing outlook provides critical insights into broader economic health and potential recovery trajectories. While the current indicators remain conservative, there are underlying signals of resilience and potential for future growth as businesses continue to innovate and optimize their operational strategies.

Manufacturing's Silent Storm: Decoding the Economic Undercurrents Reshaping American Industry

In the intricate landscape of economic indicators, manufacturing stands as a critical barometer of national economic health, reflecting deeper systemic shifts and potential challenges that extend far beyond factory floors. The current manufacturing outlook presents a nuanced narrative of transformation, resilience, and strategic adaptation in an increasingly complex global marketplace.Navigating Turbulent Economic Waters: A Comprehensive Manufacturing Insight

The Emerging Paradigm of Manufacturing Dynamics

The contemporary manufacturing sector is experiencing unprecedented metamorphosis, driven by technological disruption, global supply chain recalibration, and evolving economic pressures. Traditional manufacturing models are being systematically dismantled and reconstructed through advanced technologies like artificial intelligence, robotics, and predictive analytics. These technological interventions are not merely incremental improvements but fundamental reimaginings of production processes. Manufacturers are increasingly recognizing the imperative of digital transformation. The integration of smart manufacturing technologies enables unprecedented levels of efficiency, precision, and adaptability. Machine learning algorithms now predict maintenance requirements, optimize production schedules, and identify potential bottlenecks before they manifest, representing a quantum leap in operational intelligence.Economic Indicators and Structural Challenges

Recent economic data suggests a complex landscape characterized by subdued manufacturing activity. The persistent challenges stem from multifaceted sources: global trade tensions, fluctuating raw material costs, labor market dynamics, and technological disruption. These interconnected factors create a challenging environment where traditional performance metrics struggle to capture the nuanced realities of modern manufacturing. The current manufacturing index reveals underlying structural shifts rather than temporary cyclical fluctuations. Businesses are recalibrating strategies, focusing on lean manufacturing principles, just-in-time production models, and enhanced supply chain resilience. This strategic pivot represents a profound reevaluation of manufacturing's role in the broader economic ecosystem.Technological Innovation as a Competitive Differentiator

Technological innovation has emerged as the primary catalyst for manufacturing competitiveness. Companies investing in advanced manufacturing technologies are demonstrating remarkable adaptability and resilience. The convergence of Internet of Things (IoT), artificial intelligence, and advanced robotics is creating intelligent manufacturing environments that can rapidly respond to market dynamics. The implementation of these technologies goes beyond operational efficiency. They represent a fundamental reimagining of manufacturing's potential, transforming factories from traditional production centers into sophisticated, data-driven ecosystems. This technological evolution enables unprecedented levels of customization, quality control, and predictive maintenance.Global Supply Chain Reconfiguration

The manufacturing landscape is experiencing a profound geographical and strategic reconfiguration. Companies are reevaluating global supply chain strategies, driven by geopolitical uncertainties, pandemic-induced disruptions, and the imperative of regional resilience. This trend towards nearshoring and diversification reflects a strategic response to systemic vulnerabilities exposed in recent years. Manufacturers are developing more robust, flexible supply chain architectures that prioritize risk mitigation and adaptability. The ability to quickly pivot production, source alternative materials, and maintain operational continuity has become a critical competitive advantage in an increasingly unpredictable global environment.Workforce Transformation and Skill Development

The evolving manufacturing ecosystem demands a radical reimagining of workforce capabilities. Traditional manufacturing roles are being systematically replaced or augmented by technological interventions. This transition necessitates comprehensive reskilling and upskilling initiatives to ensure workforce relevance in a rapidly transforming industrial landscape. Educational institutions and corporations are collaborating to develop adaptive learning frameworks that equip workers with the technological and analytical skills required in modern manufacturing environments. The future workforce will be characterized by a hybrid skill set combining technical proficiency, digital literacy, and adaptive problem-solving capabilities.RELATED NEWS

Manufacturing

Manufacturing Powerhouse: Georgia Unveils Groundbreaking Digital Platform to Supercharge Industry Growth

2025-03-08 15:48:00

Manufacturing

Apple's Massive U.S. Bet: Inside the Tech Giant's Groundbreaking Investment

2025-02-24 19:21:00

Manufacturing

Tuna Can Recall Alert: Manufacturing Mishap Sparks Nationwide Food Safety Scare

2025-02-14 21:31:18