Inside DELMIA: How Smart Manufacturing is Revolutionizing Supply Chain Productivity

Manufacturing

2025-02-14 11:40:57Content

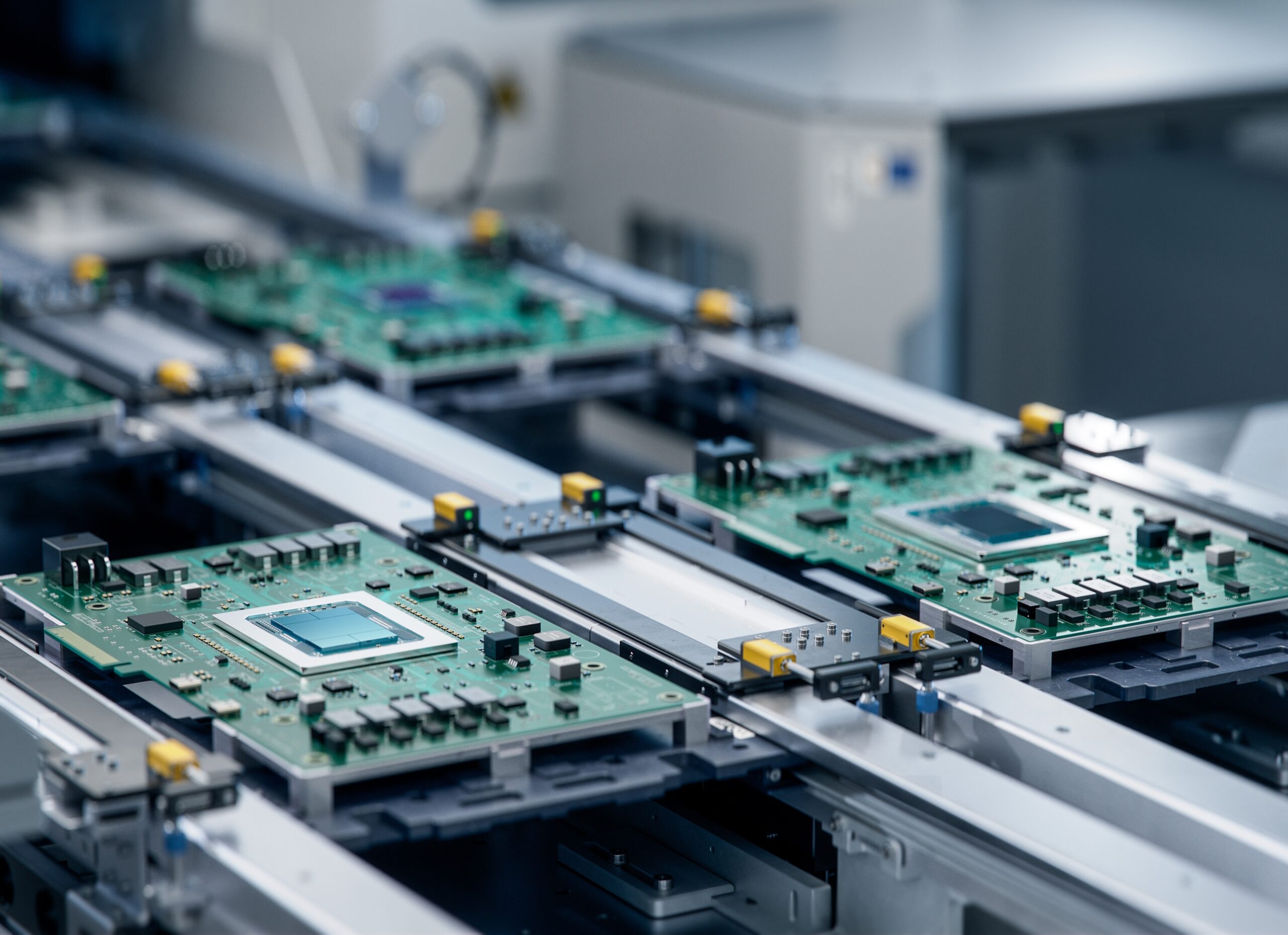

Revolutionizing Supply Chain Efficiency: The Power of Industrial IoT Connectivity

In today's hyper-competitive manufacturing landscape, businesses are constantly seeking innovative strategies to streamline operations and gain a competitive edge. Industrial Internet of Things (IIoT) connectivity has emerged as a game-changing solution, offering manufacturers unprecedented insights and transformative capabilities across their supply chains.

Breaking Down Operational Silos

Traditional manufacturing environments have long been plagued by fragmented communication and disconnected systems. IIoT technology dismantles these barriers, creating a seamless, interconnected ecosystem where real-time data flows effortlessly between machines, processes, and decision-makers.

Key Benefits of IIoT Integration

- Enhanced Visibility: Gain comprehensive, real-time insights into every stage of production and logistics

- Predictive Maintenance: Anticipate equipment failures before they occur, minimizing costly downtime

- Optimized Resource Allocation: Make data-driven decisions that maximize efficiency and reduce waste

Transforming Supply Chain Dynamics

By leveraging advanced sensor technologies and intelligent connectivity, manufacturers can create adaptive, responsive supply chains that react instantaneously to changing market demands. This dynamic approach enables businesses to reduce inventory costs, improve product quality, and accelerate time-to-market.

The Future is Connected

As digital transformation continues to reshape industrial landscapes, IIoT connectivity represents more than just a technological upgrade—it's a strategic imperative for manufacturers committed to staying ahead of the curve.

Embracing this technology isn't just about implementing new tools; it's about reimagining how manufacturing ecosystems can operate with unprecedented intelligence and efficiency.

Revolutionizing Manufacturing: The Digital Transformation of Supply Chain Connectivity

In the rapidly evolving landscape of modern manufacturing, technological innovation has become the cornerstone of competitive advantage. As industries grapple with increasingly complex global supply chains, the integration of advanced digital technologies emerges as a critical strategy for businesses seeking to optimize operational efficiency and maintain a cutting-edge market position.Unlock the Future: How Industrial IoT is Redefining Manufacturing Excellence

The Digital Revolution in Manufacturing Ecosystems

The manufacturing sector stands at a pivotal moment of technological transformation. Traditional supply chain models are being systematically dismantled and reconstructed through sophisticated digital interconnectivity. Industrial Internet of Things (IIoT) technologies are not merely incremental improvements but fundamental reimaginings of how manufacturing organizations conceptualize and execute their operational strategies. Modern manufacturers are discovering that digital connectivity transcends simple data collection. It represents a holistic approach to understanding and optimizing complex industrial ecosystems. By implementing advanced sensor technologies and real-time data analytics, companies can create unprecedented levels of visibility and responsiveness across their entire supply chain infrastructure.Connectivity as a Strategic Competitive Advantage

Technological integration represents more than a technical upgrade—it's a strategic imperative for survival in a hyper-competitive global marketplace. Companies that successfully implement IIoT solutions can achieve remarkable transformations in operational efficiency, predictive maintenance, and resource allocation. The most sophisticated organizations are developing intelligent, adaptive supply chain networks that can dynamically respond to market fluctuations, potential disruptions, and emerging opportunities. These systems leverage machine learning algorithms and advanced predictive analytics to generate insights that were previously impossible to obtain through traditional management approaches.Breaking Down Technological Barriers

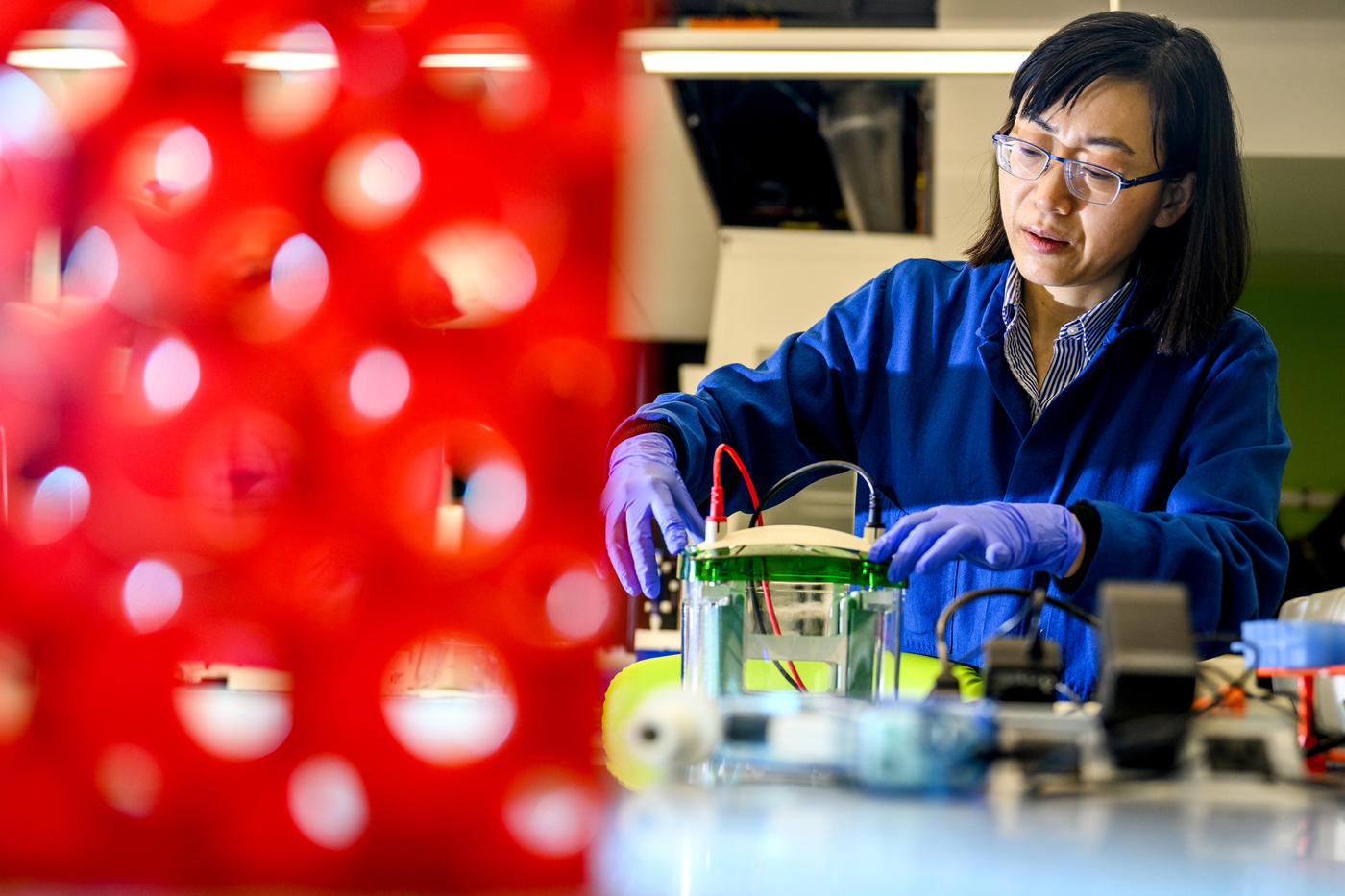

Implementing comprehensive IIoT solutions requires a multifaceted approach that addresses technological, cultural, and organizational challenges. Successful digital transformation demands more than just technological investment—it necessitates a fundamental reimagining of organizational processes and workforce capabilities. Companies must invest in comprehensive training programs, develop robust cybersecurity protocols, and create flexible technological infrastructures that can adapt to rapidly changing technological landscapes. This holistic approach ensures that technological investments translate into tangible operational improvements and sustainable competitive advantages.The Human Element in Technological Transformation

While advanced technologies drive innovation, human expertise remains the critical catalyst for successful implementation. Skilled professionals who can bridge technological capabilities with strategic business objectives are becoming increasingly valuable in the modern manufacturing ecosystem. Organizations must cultivate a culture of continuous learning and technological adaptability. This involves not just training existing workforce but also developing recruitment strategies that attract top technological talent capable of driving digital transformation initiatives.Future-Proofing Manufacturing Strategies

As global supply chains become increasingly complex and interconnected, the ability to leverage advanced digital technologies will separate industry leaders from followers. Companies that proactively invest in IIoT connectivity will be better positioned to navigate unprecedented levels of market volatility and technological disruption. The journey toward comprehensive digital transformation is ongoing, requiring persistent innovation, strategic investment, and a willingness to challenge existing operational paradigms. By embracing these principles, manufacturers can unlock new dimensions of efficiency, resilience, and competitive advantage in an increasingly digital world.RELATED NEWS

Behind the Code: How Software Is Quietly Revolutionizing Automation

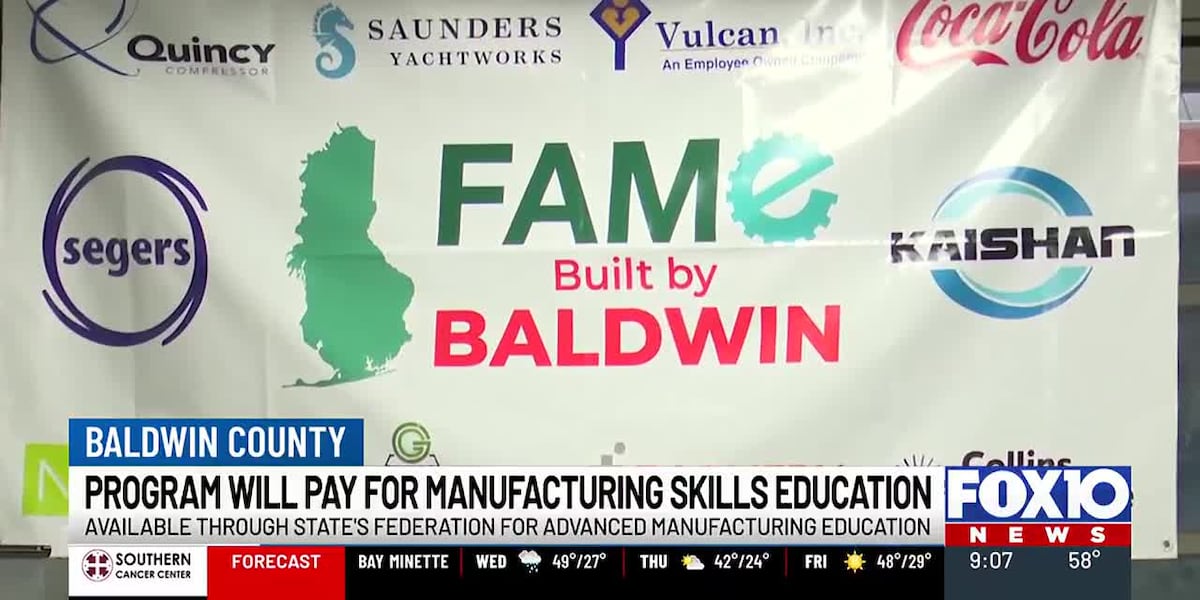

From Classroom to Career: How FAME is Revolutionizing Manufacturing Workforce Development