Trade War Fallout: How Tariffs Are Silently Crushing American Manufacturing's Competitive Edge

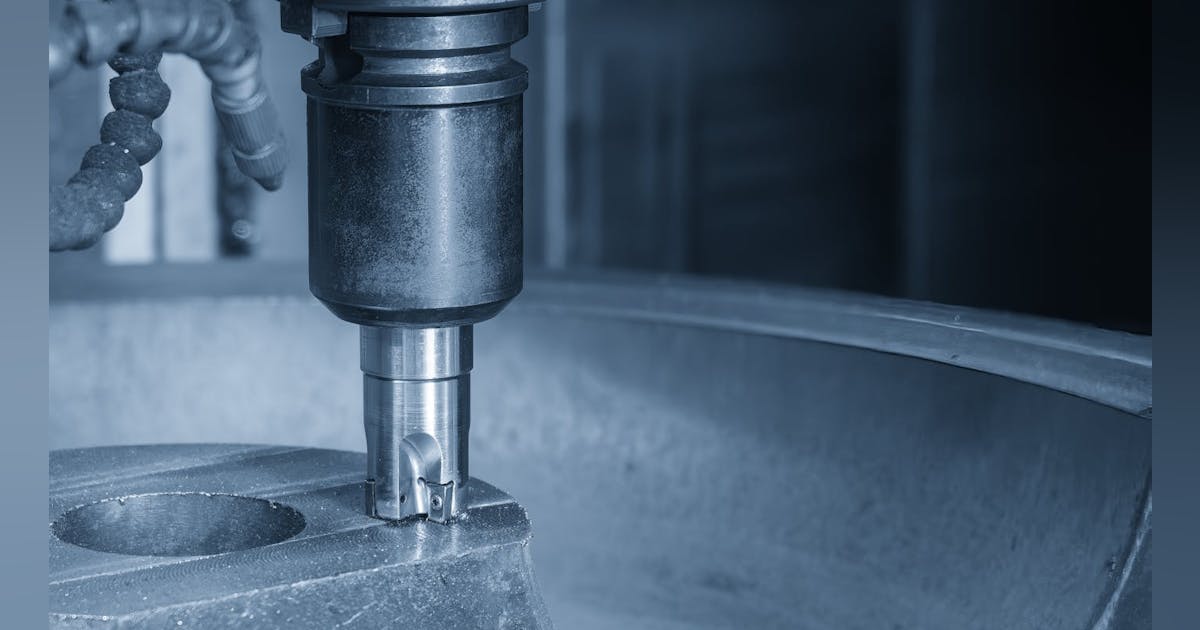

Manufacturing

2025-03-10 13:00:00Content

The North American manufacturing landscape is deeply interconnected, with Canada and Mexico playing pivotal roles in supplying critical inputs to U.S. industrial production. In a remarkable testament to regional economic integration, approximately one-third of all manufacturing components and materials utilized in the United States originate from its closest neighbors.

This robust cross-border supply chain highlights the intricate economic relationships between the United States, Canada, and Mexico. The seamless flow of manufacturing inputs underscores the strategic importance of regional trade partnerships and the interdependence of North American industries.

From advanced automotive components to sophisticated technological parts, these cross-border contributions demonstrate the strength and efficiency of the continent's manufacturing ecosystem. The substantial proportion of inputs sourced from Canada and Mexico not only supports U.S. manufacturing capabilities but also reinforces the economic bonds that unite these nations.

North American Manufacturing: The Intricate Web of Transnational Industrial Collaboration

In the complex landscape of global manufacturing, the economic ties between the United States, Canada, and Mexico represent a remarkable testament to interconnected industrial ecosystems. The boundaries of production have long since transcended national borders, creating a sophisticated network of supply chains that challenge traditional notions of economic independence.Powering Economic Synergy Through Cross-Border Manufacturing Partnerships

The Trilateral Manufacturing Ecosystem

The North American manufacturing landscape is a sophisticated tapestry of interdependence, where economic boundaries blur and collaborative production strategies reign supreme. The United States, Canada, and Mexico have forged an intricate industrial partnership that fundamentally reshapes understanding of regional economic dynamics. This collaborative model goes far beyond simple trade agreements, representing a deeply integrated manufacturing ecosystem where components, expertise, and technological innovations flow seamlessly across national boundaries. Manufacturers in these countries have developed extraordinarily complex supply chains that leverage unique regional strengths. Canadian precision engineering, Mexican labor cost advantages, and American technological innovation combine to create a manufacturing powerhouse that competes effectively on the global stage. The result is a dynamic economic environment where approximately one-third of all U.S. manufacturing inputs are sourced from Canadian and Mexican producers.Economic Interdependence and Strategic Advantages

The strategic implications of this manufacturing collaboration are profound and multifaceted. By creating an integrated production network, these nations have developed a resilient economic model that offers significant competitive advantages. Canadian manufacturers, for instance, provide high-precision components for automotive and aerospace industries, while Mexican facilities offer cost-effective manufacturing capabilities that enable complex product development at competitive price points. American companies benefit immensely from this trilateral arrangement, gaining access to diverse manufacturing capabilities that would be challenging or prohibitively expensive to replicate domestically. The proximity of these nations further enhances logistical efficiency, reducing transportation costs and enabling rapid response to market demands. This geographical advantage creates a unique economic ecosystem that promotes innovation, efficiency, and strategic collaboration.Technological Innovation and Knowledge Transfer

Beyond raw economic metrics, the North American manufacturing partnership represents a powerful platform for technological innovation and knowledge transfer. Engineers, researchers, and industrial experts from these three nations continuously exchange insights, driving technological advancements across multiple sectors. This collaborative approach accelerates innovation cycles, enabling faster product development and more sophisticated manufacturing techniques. The integration extends beyond traditional manufacturing, encompassing advanced technologies like artificial intelligence, robotics, and sustainable production methodologies. By sharing research, investing in joint technological initiatives, and creating cross-border educational and professional exchange programs, these nations are building a robust framework for future industrial development.Geopolitical and Economic Resilience

The manufacturing interconnectedness between the United States, Canada, and Mexico serves as a critical mechanism for economic resilience. By diversifying supply chains and creating a robust regional production network, these nations can better withstand global economic uncertainties. The COVID-19 pandemic dramatically highlighted the importance of such flexible, integrated manufacturing ecosystems. This collaborative model also provides a strategic counterbalance to global economic challenges, reducing dependence on distant manufacturing centers and creating a more stable, predictable industrial environment. The ability to quickly adapt, redistribute production capabilities, and leverage regional strengths becomes an increasingly valuable economic strategy in an unpredictable global landscape.RELATED NEWS

Manufacturing

Tragic Workplace Incident: Fatal Accident Claims Worker's Life at York County Manufacturing Facility

2025-03-03 04:29:00

Manufacturing

Silicon and Sacrifice: The Hidden Cost of America's Microchip Revolution

2025-02-19 14:00:00

Manufacturing

Manufacturing Revolution: Foxconn Unveils Cutting-Edge Chinese AI Language Model

2025-03-10 13:00:09