AI Boom Drives Flex's Texas Expansion: New Dallas Plant Supercharges Power Manufacturing

Manufacturing

2025-02-20 14:05:00Content

Flex Accelerates U.S. Manufacturing Footprint with Massive Dallas Facility Expansion

In a strategic move to bolster domestic manufacturing capabilities, Flex (NASDAQ: FLEX) has unveiled plans to significantly enhance its production infrastructure. The technology solutions provider is set to establish a cutting-edge 400,000-square-foot manufacturing facility in Dallas, marking a substantial investment in U.S. industrial capacity.

This expansive new manufacturing complex represents Flex's commitment to strengthening domestic production capabilities and responding to growing demand for advanced manufacturing solutions. The state-of-the-art facility will leverage Flex's renowned expertise in precision engineering and innovative manufacturing technologies.

By expanding its U.S. manufacturing presence, Flex is positioning itself to provide more agile, localized production services for clients across multiple industries. The Dallas facility is expected to create new job opportunities and contribute to the region's economic growth while enhancing Flex's competitive edge in the global manufacturing landscape.

The announcement underscores Flex's ongoing strategy of strategic geographic expansion and investment in advanced manufacturing infrastructure.

Flex Revolutionizes U.S. Manufacturing: A Massive Expansion Signals Industrial Renaissance

In an era of technological transformation and economic recalibration, Flex emerges as a pivotal player reshaping the manufacturing landscape of the United States. The company's strategic move to expand its manufacturing capabilities represents more than just a business decision—it's a bold statement about the future of American industrial innovation and economic resilience.Powering America's Manufacturing Future: A Strategic Industrial Breakthrough

The Dallas Facility: A Cornerstone of Manufacturing Excellence

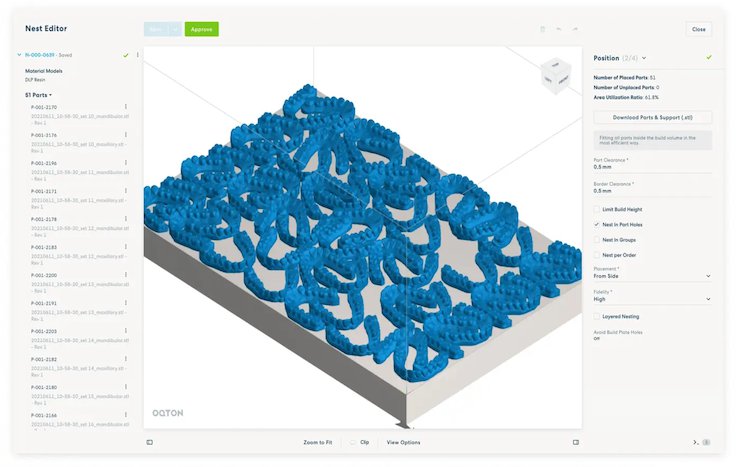

The newly announced 400,000-square-foot manufacturing facility in Dallas represents a monumental investment in American industrial infrastructure. This expansive complex is not merely a building, but a testament to Flex's commitment to technological advancement and economic growth. By strategically positioning this facility in Dallas, the company leverages the region's robust infrastructure, skilled workforce, and strategic geographical advantages. The facility's massive footprint enables Flex to dramatically increase its production capabilities, potentially transforming the regional and national manufacturing ecosystem. Advanced manufacturing technologies integrated into this space will likely set new standards for efficiency, precision, and innovation across multiple industrial sectors.Technological Innovation and Economic Impact

Flex's expansion goes beyond physical infrastructure—it represents a profound commitment to technological innovation and economic revitalization. The new manufacturing center is expected to create numerous high-skilled jobs, stimulating local economic development and providing career opportunities in advanced manufacturing. The facility's design incorporates cutting-edge sustainable technologies, reflecting a forward-thinking approach to industrial development. By prioritizing energy efficiency and modern manufacturing techniques, Flex demonstrates how contemporary industrial spaces can simultaneously drive economic growth and environmental responsibility.Strategic Positioning in a Global Manufacturing Landscape

This significant investment comes at a critical moment in global manufacturing dynamics. As supply chains continue to evolve and companies seek to reduce international dependencies, Flex's expansion represents a strategic repositioning of manufacturing capabilities within the United States. The Dallas facility is not just a production center but a potential hub of technological innovation. By investing in domestic manufacturing infrastructure, Flex signals confidence in the American industrial ecosystem and contributes to the broader narrative of reshoring and industrial renaissance.Technological Capabilities and Future Potential

While specific details about the facility's technological capabilities remain proprietary, industry experts anticipate that the new center will likely support advanced manufacturing processes across multiple sectors. From precision engineering to complex electronic assemblies, the facility is positioned to serve diverse industrial needs. The investment suggests Flex's commitment to maintaining technological leadership and adaptability in a rapidly changing global manufacturing environment. By creating a flexible, state-of-the-art manufacturing space, the company prepares itself to respond quickly to emerging market demands and technological innovations.Economic and Regional Development Implications

Beyond its immediate manufacturing objectives, the Dallas facility represents a significant catalyst for regional economic development. The project is expected to attract complementary businesses, create a robust industrial ecosystem, and potentially position the Dallas area as a key node in the national manufacturing network. Local economic development authorities are likely viewing this expansion as a transformative event, potentially sparking further investments and industrial growth in the region. The ripple effects of such a substantial manufacturing investment could reshape economic opportunities for years to come.RELATED NEWS

Manufacturing

Breaking: Lanex Manufacturing Revolutionizes Construction with Cutting-Edge Modular Frame Technology

2025-02-26 00:00:00

Manufacturing

Pharma Giant Lilly Unveils Massive U.S. Manufacturing Expansion: 4 New Sites Set to Boost Production

2025-02-27 13:51:12

Manufacturing

Skills Gap Crisis: How Indonesia's Youth Are Derailing the Manufacturing Boom

2025-03-10 23:00:02