Beyond Pixels: How GM is Revolutionizing Pre-Production with Virtual Reality

Manufacturing

2025-03-11 10:30:00

General Motors is revolutionizing automotive pre-production through cutting-edge virtual technology, setting a new standard for vehicle development and manufacturing excellence. By leveraging advanced digital simulation and modeling techniques, GM is transforming how vehicles are designed, tested, and refined before they ever touch the physical production line. This innovative virtual-led strategy enables GM's engineering teams to dramatically enhance vehicle performance, reliability, and manufacturing efficiency. Through sophisticated computer simulations, engineers can now predict and resolve potential design challenges, optimize component interactions, and streamline the entire development process with unprecedented precision. The approach allows GM to conduct extensive virtual testing across multiple scenarios, reducing physical prototype costs and accelerating time-to-market. By creating highly detailed digital models, the company can simulate complex engineering challenges, stress test vehicle systems, and validate design concepts with remarkable accuracy. Key benefits of GM's virtual strategy include: • Faster product development cycles • Reduced engineering and prototyping expenses • Enhanced vehicle performance and reliability • More sustainable and efficient manufacturing processes As automotive technology continues to evolve, GM's commitment to virtual-led innovation positions the company at the forefront of next-generation vehicle design and production. MORE...

Tower Power: Zedcor Scales Production and Dodges Trade Challenges

Manufacturing

2025-03-11 10:00:00

Zedcor Inc. Accelerates Manufacturing Capacity, Surpasses Production Targets Calgary, Alberta - Zedcor Inc. (TSXV: ZDC) is making impressive strides in its manufacturing capabilities, announcing a significant breakthrough in production efficiency. The company has successfully ramped up its tower manufacturing to an impressive 25 towers per week, outpacing its original budgeted timeline. Looking ahead, Zedcor is poised for even greater expansion, with plans to increase production to 30 towers per week in the second quarter of 2025. This ambitious scaling is being supported by component suppliers who are aligning their capabilities with Zedcor's growth strategy. The company has now adjusted its manufacturing target for 2025 to a robust 1,200-1,400 towers, signaling strong market demand and operational excellence. This milestone underscores Zedcor's commitment to innovation and strategic growth in its industry. Investors and stakeholders can look forward to continued progress as Zedcor continues to optimize its production processes and expand its manufacturing capabilities. MORE...

Solar Power Revolution: How Kimberly-Clark and BNZ Are Transforming Green Manufacturing

Manufacturing

2025-03-11 09:00:00

In a strategic move towards sustainability, Kimberly-Clark has forged a groundbreaking partnership with BNZ to implement three virtual Power Purchase Agreements (vPPAs) across Italy and Spain. This innovative collaboration aims to significantly reduce the Scope 2 emissions of the company's European manufacturing facilities, demonstrating Kimberly-Clark's commitment to environmental responsibility and clean energy transformation. By leveraging these virtual Power Purchase Agreements, the global consumer goods company is taking a proactive approach to minimizing its carbon footprint and supporting the transition to renewable energy sources. The initiative not only underscores Kimberly-Clark's environmental leadership but also sets a powerful example for other multinational corporations seeking to address climate change through strategic energy solutions. MORE...

Robots, Algorithms, and Assembly Lines: How AI is Transforming Manufacturing's Future

Manufacturing

2025-03-11 09:00:00

AI Revolution: Transforming Manufacturing's Future

In an illuminating panel discussion, industry experts Steve Plumb, John Star from Methods Machine Tools, and Mike Kaminski Jr. of Multiaxis, LLC, delved deep into the transformative potential of artificial intelligence in modern manufacturing.

The conversation explored critical challenges facing the manufacturing sector, including workforce dynamics, sophisticated data management strategies, and the emerging landscape of intelligent, interconnected smart factories. These thought leaders shared compelling insights into how AI is not just a technological trend, but a fundamental reshaping of industrial production.

From addressing skilled labor shortages to leveraging advanced data analytics, the panelists painted a vivid picture of a manufacturing ecosystem where technology and human expertise converge to drive unprecedented efficiency and innovation.

As AI continues to evolve, manufacturers are standing at the cusp of a technological revolution that promises to redefine productivity, precision, and competitive advantage in the global industrial marketplace.

MORE...Breaking: SG Wireless Expands Global Manufacturing Ties to Solve OEM Supply Chain Puzzle

Manufacturing

2025-03-11 08:00:00

SG Wireless Strengthens Strategic Alliance with Season Group to Advance IoT Technology Solutions

In a significant strategic move, SG Wireless Limited, a leading innovator in Internet of Things (IoT) technology solutions, has announced the deepening of its partnership with parent company Season Group. This collaboration marks a pivotal moment in the company's commitment to driving technological advancement and expanding its market presence.

The partnership aims to leverage the combined expertise and resources of both organizations to develop cutting-edge IoT solutions that address emerging market needs. By aligning their technological capabilities and strategic vision, SG Wireless and Season Group are positioning themselves at the forefront of the rapidly evolving IoT landscape.

Through this strengthened alliance, the companies expect to accelerate product development, enhance innovation, and create more comprehensive technology solutions that can transform industries and improve operational efficiency for their clients.

As IoT continues to reshape the technological ecosystem, this strategic partnership underscores SG Wireless's dedication to pushing the boundaries of connected technology and delivering value-driven solutions to businesses worldwide.

MORE...Solar Revolution: Graphene Electrodes Set to Dethrone Silver in Photovoltaic Manufacturing

Manufacturing

2025-03-11 07:56:00

A cutting-edge university spinoff born from Swiss and British innovation is set to revolutionize solar cell manufacturing. GraphEnergyTech, an emerging technology company, is pioneering groundbreaking graphene electrode technology that promises to displace traditional metal components like silver in solar panel production. By leveraging the remarkable properties of graphene—a super-thin, incredibly strong carbon material—the startup aims to introduce a more efficient and potentially cost-effective alternative to conventional metallic electrodes. This innovative approach could significantly transform the solar energy landscape, offering manufacturers a sophisticated solution that enhances solar cell performance and reduces production expenses. The company's research represents a promising intersection of advanced materials science and renewable energy technology, signaling a potential leap forward in sustainable power generation. As the global demand for cleaner energy solutions continues to grow, GraphEnergyTech's graphene-based electrode technology stands poised to make a meaningful impact in the solar industry. MORE...

Drone Tech Breakthrough: Sphere Supercharges HubX with Australian Manufacturing Muscle

Manufacturing

2025-03-11 07:03:00

Sphere Drones is taking a bold leap forward by internalizing its manufacturing process, aiming to dramatically accelerate the production of its innovative HubX drone-in-a-box system. This strategic move signals the company's commitment to scaling up its technological capabilities and reducing dependency on external supply chains. By bringing manufacturing in-house, Sphere Drones is poised to gain greater control over production quality, reduce lead times, and potentially lower overall manufacturing costs. The HubX drone-in-a-box represents a cutting-edge autonomous drone solution designed for versatile applications across industries such as surveillance, infrastructure inspection, and emergency response. The decision to internalize manufacturing reflects a growing trend among tech companies seeking to streamline operations and maintain a competitive edge in the rapidly evolving drone technology landscape. With this approach, Sphere Drones is positioning itself as a more agile and responsive player in the autonomous drone market. As the company ramps up its internal production capabilities, customers can expect faster deployment, more customized solutions, and potentially more innovative features in future iterations of the HubX system. This strategic transformation underscores Sphere Drones' ambition to be at the forefront of autonomous drone technology. MORE...

Medical Device Manufacturing Giants TE Connectivity and Sanmina Poised to Revolutionize Global Healthcare Market by 2032

Manufacturing

2025-03-11 05:33:33

Medical Device Contract Manufacturing: A Market Poised for Remarkable Growth

The medical device contract manufacturing sector is experiencing an extraordinary trajectory of expansion, with recent market analysis revealing impressive growth potential. In 2022, the market demonstrated substantial strength, reaching a valuation of US$ 88.8 billion. Projections indicate a remarkable surge, with expectations to escalate to US$ 192.3 billion by 2030.

This anticipated growth represents a robust compound annual growth rate (CAGR) of 10.2%, signaling robust opportunities and increasing demand within the medical device manufacturing landscape. The steady upward trend reflects the industry's critical role in supporting healthcare innovation, technological advancements, and the global medical device supply chain.

Factors driving this impressive market expansion include increasing healthcare investments, rising chronic disease prevalence, technological innovations, and the growing trend of outsourcing medical device production to specialized contract manufacturers.

As healthcare continues to evolve, the medical device contract manufacturing market stands at the forefront of transformative change, promising significant economic and technological developments in the coming years.

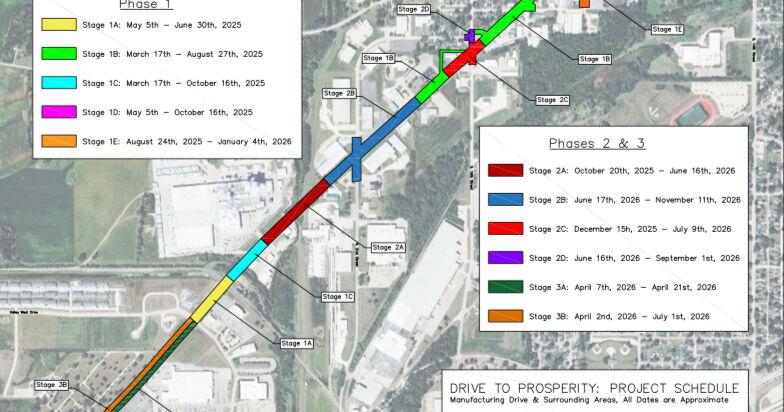

MORE...Industrial Innovation Launches: Manufacturing Drive Project Kicks Off Next Month

Manufacturing

2025-03-11 04:00:00

Transforming Transportation: Major Infrastructure Upgrade Launches This March A comprehensive road improvement initiative, dubbed the Manufacturing Drive Project, is set to kick off on Tuesday, March 18th. This ambitious infrastructure overhaul aims to revolutionize local transportation by addressing critical roadway challenges and enhancing overall travel experience. The project will focus on three key strategic areas: improving road conditions, expanding transportation capacity, and modernizing infrastructure. These comprehensive upgrades are designed to significantly boost safety standards and optimize traffic flow throughout the region. Transportation officials emphasize that the project represents a significant investment in the community's long-term mobility and connectivity. By implementing cutting-edge infrastructure solutions, the initiative promises to deliver smoother, more efficient travel for residents and commuters alike. Drivers and local residents are encouraged to stay informed about potential traffic modifications and construction zones during the project's implementation phase. Detailed updates and progress reports will be made available through official municipal channels. MORE...

Behind the Curtain: China's Defense Industry Secrets Exposed

Manufacturing

2025-03-11 02:44:20

In the complex landscape of global defense manufacturing, the Stockholm International Peace Research Institute (Sipri) has drawn attention to China's remarkable ascent in military production. However, the report conspicuously sidesteps a critical aspect of Beijing's technological strategy: its widespread practice of reverse engineering foreign military technologies. In stark contrast, India's Atmanirbhar Bharat (Self-Reliant India) initiative takes a more principled approach. While progress may be slower, the initiative demonstrates a commitment to ethical and indigenous defense production. Unlike China's opportunistic technology acquisition methods, India is methodically building its defense capabilities through genuine innovation and technological development. This nuanced approach highlights the fundamental difference between rapid technological appropriation and sustainable, principled self-reliance in the defense sector. India's strategy, though gradual, promises a more robust and ethically grounded path to technological independence. MORE...