Global Marine Powerhouse: Twin Disc Expands Empire with Strategic $16.5M Buyout

Manufacturing

2025-02-18 13:00:00

Twin Disc, a global leader in marine and industrial power transmission technologies, has strategically expanded its global footprint by acquiring Kobelt Manufacturing. This landmark acquisition not only adds a robust $14 million revenue stream to the company's portfolio but also significantly enhances its international presence across 60 countries. The strategic move brings Kobelt Manufacturing's specialized expertise in marine control systems and precision engineering into Twin Disc's comprehensive product lineup. By integrating Kobelt's innovative technologies and established market reputation, Twin Disc reinforces its commitment to delivering cutting-edge solutions in marine and industrial sectors. This acquisition represents more than just a financial transaction; it's a testament to Twin Disc's ongoing strategy of growth through strategic partnerships and technological diversification. The addition of Kobelt Manufacturing will enable Twin Disc to offer more comprehensive and advanced power transmission solutions to its global customer base. With this expansion, Twin Disc continues to solidify its position as a key player in the marine and industrial equipment market, demonstrating its ability to adapt, innovate, and grow in a competitive global landscape. MORE...

Dental Tech Revolution: Axtra3D and Oqcam Forge Powerful Alliance to Transform 3D Printing Workflows

Manufacturing

2025-02-18 13:00:00

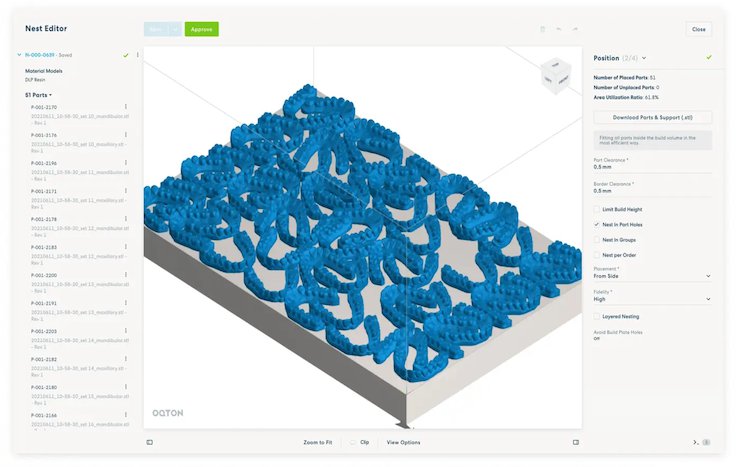

Oqcam and Axtra3D are revolutionizing the 3D printing workflow by combining cutting-edge artificial intelligence with advanced stereolithography (SLA) technology. Their collaborative solution aims to streamline the build preparation process, dramatically reducing manual intervention and increasing overall efficiency. By leveraging Oqcam's intelligent AI-driven automated nesting capabilities, manufacturers can now optimize part placement and orientation with unprecedented precision. This innovative integration promises to significantly cut down setup time, allowing businesses to accelerate their production cycles and minimize human error. The partnership represents a significant leap forward in additive manufacturing, demonstrating how artificial intelligence can transform traditional manufacturing processes. Engineers and production managers can now rely on smart algorithms to handle complex build preparation tasks, freeing up valuable human resources for more strategic activities. As 3D printing continues to evolve, collaborations like this highlight the potential of AI to enhance manufacturing productivity and precision, setting new standards for automated production workflows. MORE...

Pharma Giants Lonza and Aurobindo Set to Revolutionize Contract Manufacturing: Explosive Market Growth Predicted by 2032

Manufacturing

2025-02-18 10:35:42

The Contract Pharmaceutical Manufacturing Market is poised for remarkable growth, with projections indicating a substantial expansion to USD 450.07 billion by 2032. Industry analysts forecast an impressive compound annual growth rate (CAGR) of 9.9% between 2025 and 2032, signaling robust opportunities in the pharmaceutical outsourcing landscape. This remarkable trajectory reflects the increasing complexity of drug development, rising global healthcare demands, and pharmaceutical companies' strategic shift towards more flexible and cost-effective manufacturing models. Contract manufacturers are becoming critical partners in bringing innovative therapies to market, offering specialized expertise, advanced technological capabilities, and scalable production solutions. Key drivers propelling this market expansion include the growing complexity of pharmaceutical research, the need for specialized manufacturing capabilities, and the rising costs of in-house production. Emerging markets, technological advancements, and the ongoing trend of pharmaceutical companies focusing on core research and development are further accelerating the growth of contract pharmaceutical manufacturing. As the industry continues to evolve, contract manufacturers are expected to play an increasingly pivotal role in transforming pharmaceutical production, delivering innovative solutions that bridge the gap between scientific discovery and global healthcare accessibility. MORE...

Machines of Tomorrow: How AI is Revolutionizing the Factory Floor

Manufacturing

2025-02-18 10:00:00

The Digital Revolution: How AI and Technology Are Reshaping Manufacturing

In an era of rapid technological transformation, the manufacturing industry is experiencing a groundbreaking shift. At the forefront of this revolution is the integration of artificial intelligence and digital technologies that are fundamentally reimagining traditional production processes.

Matt Belkin, CEO of Parsable, offers a compelling vision of this technological evolution. He emphasizes the critical need to move beyond outdated paper-based systems that have long hindered operational efficiency. By embracing digital solutions, manufacturers can dramatically streamline workflows, enhance productivity, and address persistent labor challenges.

The current manufacturing landscape faces significant hurdles, including skilled labor shortages and the need for more adaptive, responsive production methods. AI and digitization provide powerful tools to overcome these obstacles, enabling companies to:

- Automate complex operational processes

- Reduce human error

- Optimize workforce management

- Improve real-time decision-making

As industries continue to evolve, those who embrace technological innovation will not just survive, but thrive in an increasingly competitive global marketplace. The future of manufacturing is digital, intelligent, and boundlessly innovative.

MORE...Driving Sustainability: GIC Launches Groundbreaking Automotive Plastics Recycling Initiative

Manufacturing

2025-02-18 10:00:00

In a groundbreaking initiative, the Global Impact Coalition has joined forces with seven pioneering global chemical and recycling industry leaders, including industry giants BASF, Mitsubishi Chemical Group, and Covestro. These innovative companies are spearheading a transformative pilot project that promises to revolutionize sustainable materials and recycling technologies. By combining their expertise and resources, these industry leaders are setting a new standard for environmental innovation and circular economy solutions. MORE...

Inside the Chemistry Lab: Revolutionizing Potassium Acetate Production from Scratch

Manufacturing

2025-02-18 09:52:25

Establishing a Cutting-Edge Potassium Acetate Manufacturing Facility: A Comprehensive Strategic Blueprint Launching a successful potassium acetate production facility requires a meticulous and multifaceted approach that goes far beyond simple industrial planning. This complex endeavor demands a sophisticated strategy encompassing several critical dimensions of industrial development. Market Intelligence and Strategic Positioning The foundation of a robust manufacturing initiative begins with comprehensive market research. Investors and project managers must conduct an in-depth analysis of current market dynamics, potential demand trajectories, competitive landscapes, and emerging industry trends specific to potassium acetate applications. Operational Architecture A successful facility hinges on precise operational planning, which includes: • Intricate unit process design • Strategic raw material sourcing • Comprehensive utility infrastructure • Advanced technological integration • Sophisticated machinery selection • Robust logistics frameworks Technical and Human Capital Considerations Beyond technical specifications, successful implementation requires: • Specialized workforce recruitment • Comprehensive training programs • Advanced technological skill development • Safety and compliance protocols Financial and Strategic Modeling Critical financial considerations include: • Capital investment strategies • Return on investment projections • Risk mitigation frameworks • Long-term sustainability planning By synthesizing these multifaceted elements, organizations can develop a world-class potassium acetate manufacturing facility positioned for sustainable growth and technological leadership. MORE...

Shatterproof Success: Inside the High-Stakes World of Bulletproof Glass Manufacturing

Manufacturing

2025-02-18 09:36:31

Establishing a Cutting-Edge Bulletproof Glass Manufacturing Facility: A Comprehensive Strategic Guide Launching a successful bulletproof glass manufacturing operation requires a meticulous and multifaceted approach that goes far beyond simple production planning. Entrepreneurs and industrial strategists must navigate a complex landscape of market dynamics, technological innovations, and operational intricacies. The journey begins with an in-depth market analysis that reveals critical insights into industry demand, potential customer segments, and competitive positioning. This foundational research provides the strategic blueprint for developing a robust and competitive manufacturing facility. Key strategic considerations include: 1. Market Intelligence - Comprehensive demand assessment - Identification of target industries - Competitive landscape evaluation 2. Operational Infrastructure - Precision unit process design - Strategic raw material sourcing - Advanced utility and infrastructure planning 3. Technological Capabilities - State-of-the-art machinery selection - Cutting-edge manufacturing technologies - Quality control and precision engineering systems 4. Human Capital Development - Specialized workforce recruitment - Technical training programs - Safety and skill enhancement initiatives 5. Financial and Logistical Framework - Detailed capital investment planning - Supply chain optimization - Distribution network development By meticulously addressing these critical dimensions, entrepreneurs can create a resilient and innovative bulletproof glass manufacturing facility positioned for sustainable growth and market leadership. MORE...

Inferno Erupts: Pennsylvania Aviation Factory Consumed by Massive Blaze

Manufacturing

2025-02-18 09:18:07

In a swift response to an emergency, the Abington Township Police Department successfully evacuated a local building following an incident. Authorities quickly took action, ensuring the safety of all employees by confirming their complete evacuation and accounting for every individual on the premises. While the immediate threat has been addressed, investigators are still working to determine the origin of the fire. At this time, the cause remains a mystery, with police continuing their investigation to uncover the circumstances that led to the incident. The prompt and professional handling of the situation by local law enforcement demonstrates the community's preparedness and commitment to public safety. MORE...

Fashion Revolution: How Digital Printing is Crushing Traditional Textile Manufacturing

Manufacturing

2025-02-18 09:00:00

Manufacturing Digital recently had the privilege of attending Epson's groundbreaking unveiling of their new Textile Innovation Centre in the United Kingdom. The event was a vibrant showcase of cutting-edge textile technology, offering an exciting glimpse into the future of sustainable and innovative manufacturing processes. The launch event illuminated the immense potential of Epson's latest textile innovations, demonstrating how advanced technology can revolutionize the textile industry. Visitors were treated to an immersive experience that highlighted the centre's commitment to pushing the boundaries of textile production, sustainability, and design. Epson's new facility represents a significant milestone in textile manufacturing, promising to transform traditional approaches with state-of-the-art solutions that prioritize both technological excellence and environmental responsibility. MORE...

From Abandoned to Alive: QuaLex Manufacturing Revives Dormant Joy Plant 1

Manufacturing

2025-02-18 09:00:00

A Historic Industrial Site Transforms: The Revitalization of Joy Plant 1 In the heart of Franklin, an exciting urban renewal project is breathing new life into the historic Joy Plant 1 facility. What was once a dormant industrial landmark is now poised to become a vibrant hub of innovation and community development. The transformation represents more than just a renovation; it's a testament to the city's commitment to preserving its industrial heritage while creating forward-looking spaces. Local developers and city planners have collaborated to reimagine the site, blending its rich historical character with modern architectural design and functional versatility. Preliminary plans suggest the facility will host a mix of commercial, creative, and potentially residential spaces. This adaptive reuse strategy not only preserves an important piece of Franklin's industrial history but also promises to inject new economic energy into the neighborhood. Community members and local business leaders have expressed enthusiasm about the project, seeing it as a significant milestone in the area's ongoing urban revitalization efforts. The Joy Plant 1 project symbolizes the potential for thoughtful urban regeneration, turning forgotten industrial spaces into dynamic, multi-purpose environments that serve contemporary needs. As renovations progress, the site stands as a promising example of how cities can honor their past while building innovative futures. MORE...