Automotive Apocalypse: How Trump's Policies Derailed Global Car Manufacturing

Manufacturing

2025-02-20 17:54:11

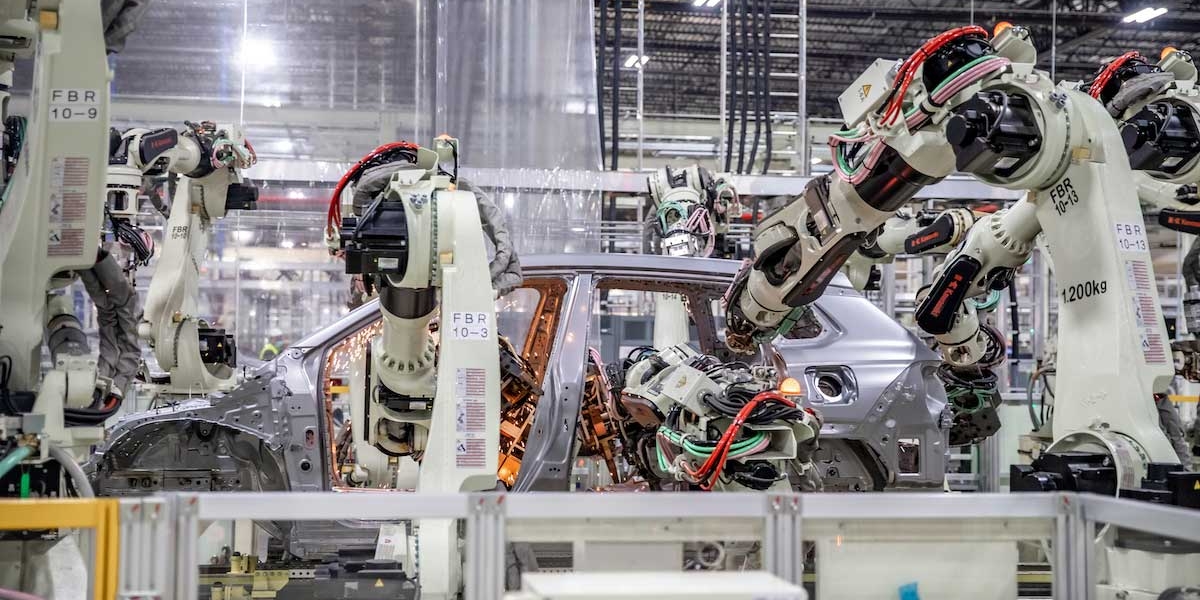

The automotive industry's intricate global supply chain has been dramatically disrupted by President Trump's tariff policies, revealing the complex interconnectedness of modern car manufacturing. What was once a seamless international production network has now become a challenging puzzle for automakers worldwide. Trump's aggressive trade measures, particularly those targeting steel and aluminum imports, have sent shockwaves through the automotive sector. Manufacturers who have long relied on cross-border component sourcing and integrated international production strategies are now forced to recalibrate their entire approach. Major car companies are experiencing significant pressure as they navigate these new economic barriers. Supply chains that were meticulously developed over decades are now being rapidly restructured, driving up production costs and creating unprecedented uncertainty. From Detroit to Tokyo, automakers are scrambling to find alternative sourcing strategies that can maintain profitability while complying with new trade restrictions. The tariffs have exposed the vulnerability of the global automotive ecosystem, demonstrating how quickly international trade policies can transform an industry's fundamental operations. Consumers may ultimately bear the brunt of these changes through higher vehicle prices and potentially reduced model variety. As the automotive world adapts to this new reality, one thing becomes clear: the era of seamless global manufacturing has been fundamentally challenged, with far-reaching implications for the industry's future. MORE...

Detroit Set to Host Cutting-Edge 3D Printing Extravaganza: RAPID + TCT 2025 Promises Innovation Explosion

Manufacturing

2025-02-20 17:00:41

Additive Manufacturing Enthusiasts Gear Up for RAPID + TCT 2025: A Cutting-Edge Convergence in Detroit The premier event for additive manufacturing innovation is set to electrify the industry once again. RAPID + TCT 2025, renowned as North America's most influential and comprehensive additive manufacturing conference, will transform Huntington Place in downtown Detroit into a hub of technological breakthrough from April 8-10. This highly anticipated event promises to bring together leading experts, pioneering manufacturers, and technology innovators from across the globe. Attendees can expect an immersive experience showcasing the latest advancements in 3D printing, advanced manufacturing techniques, and groundbreaking industrial applications. Detroit, a city with a rich manufacturing heritage, provides the perfect backdrop for this forward-thinking conference. Professionals, researchers, and industry leaders will converge to explore emerging trends, network with peers, and witness firsthand the transformative potential of additive manufacturing technologies. Mark your calendars for this unmissable event that continues to shape the future of manufacturing innovation. MORE...

Powering Progress: How Alabama's Workforce Is Reshaping American Manufacturing

Manufacturing

2025-02-20 16:31:47

Nestled in the heart of Alabama, Huntsville stands as a beacon of technological prowess and scientific achievement. For decades, this vibrant city has been at the forefront of American innovation, weaving an extraordinary narrative of human potential and exploration. From the historic Apollo missions that first carried humanity to the moon to the groundbreaking research currently unfolding at Redstone Arsenal and the Marshall Space Flight Center, Huntsville represents more than just a location—it embodies the relentless spirit of American ingenuity and discovery. The city's landscape is a living testament to human creativity, where brilliant minds continue to push the boundaries of what's possible, transforming bold ideas into world-changing technologies that inspire generations. Huntsville doesn't just dream of the future; it actively creates it, one breakthrough at a time. MORE...

Breaking: BigBloc Construction Expands Manufacturing Footprint with Strategic Land Acquisition in India

Manufacturing

2025-02-20 16:29:33

Autoclaved Aerated Concrete (AAC) Blocks: A Revolutionary Building Material In the dynamic world of modern construction, Autoclaved Aerated Concrete (AAC) blocks have emerged as a game-changing building material that is transforming architectural design and construction practices. These innovative lightweight blocks offer an impressive array of benefits that make them increasingly popular among architects, builders, and developers. AAC blocks are engineered through a unique manufacturing process that combines cement, lime, sand, and aluminum powder. When these ingredients interact, they create a remarkable cellular structure that sets AAC blocks apart from traditional construction materials. The result is an incredibly lightweight, yet strong building block that delivers exceptional thermal insulation and structural integrity. Key advantages of AAC blocks include: • Exceptional thermal efficiency • Lightweight construction • Superior sound insulation • Fire resistance • Environmentally friendly manufacturing process • Easy to cut and shape • Reduced construction time and labor costs Architects and construction professionals are increasingly recognizing AAC blocks as a sustainable and versatile solution for modern building projects. From residential homes to commercial structures, these innovative blocks are reshaping the way we think about construction materials and environmental responsibility. MORE...

Bakery Giant Paris Baguette Breaks Ground on Landmark North American Production Hub

Manufacturing

2025-02-20 15:31:45

Paris Baguette, the beloved bakery and cafe chain, is making a bold strategic move by significantly enhancing its supply chain infrastructure. The company is investing heavily to streamline operations, improve product quality, and ensure more efficient delivery of its delectable pastries and baked goods across its growing network of locations. By focusing on supply chain optimization, Paris Baguette aims to strengthen its competitive edge in the increasingly crowded bakery and cafe market. The substantial investment demonstrates the company's commitment to maintaining high standards of freshness, consistency, and customer satisfaction. This strategic initiative is expected to not only improve operational efficiency but also support the chain's ambitious expansion plans. By modernizing its supply chain, Paris Baguette can better manage inventory, reduce waste, and potentially introduce more innovative products to its loyal customer base. The move signals Paris Baguette's forward-thinking approach, positioning the brand as a leader in the competitive food service industry by leveraging technology and strategic investments to drive growth and enhance overall customer experience. MORE...

NY Manufacturing Sector Shows Resilience Despite Waning Confidence, Economic Survey Reveals

Manufacturing

2025-02-20 15:05:25

Manufacturing in New York Shows Signs of Recovery After a downturn last month, the Empire State Manufacturing survey from the Federal Reserve Bank of New York brings a glimmer of hope. The latest data reveals a modest but encouraging uptick in manufacturing activity across the state, signaling potential economic resilience. The February report indicates a slight expansion in the manufacturing sector, breaking the previous month's decline. This incremental growth suggests that local manufacturers may be navigating challenging economic conditions with cautious optimism. While the increase is modest, it represents a positive shift in the region's industrial landscape. Economists and industry experts will be closely monitoring future reports to determine whether this represents the beginning of a broader recovery or simply a temporary fluctuation in the manufacturing environment. MORE...

Green Revolution on Wheels: Hendrickson Transforms Truck Bumpers with Solar Innovation

Manufacturing

2025-02-20 15:04:48

Driving Innovation: Hendrickson Pioneers Sustainable Truck Manufacturing with Cutting-Edge Solar Initiative Hendrickson is revolutionizing the transportation industry with a groundbreaking commitment to sustainability, unveiling an impressive solar farm at its Illinois manufacturing facility. This strategic investment marks a significant milestone in the company's green technology approach, demonstrating a forward-thinking vision for eco-friendly commercial vehicle production. The new solar installation represents more than just an energy solution—it's a bold statement about Hendrickson's dedication to reducing carbon footprints and leading industrial transformation. By harnessing solar power directly at their manufacturing site, the company is not only reducing operational costs but also setting a new standard for environmental responsibility in the automotive and transportation sectors. This innovative project underscores Hendrickson's commitment to sustainable manufacturing practices, positioning the company at the forefront of green technology adoption. As the transportation industry increasingly focuses on environmental impact, Hendrickson's solar farm serves as a powerful example of how forward-thinking companies can drive meaningful change while maintaining operational excellence. MORE...

Plasma Pen Breakthrough: How Tiny Tech is Transforming Industrial Bonding Forever

Manufacturing

2025-02-20 14:23:54

Revolutionary Plasma Technology Transforms Manufacturing Precision In a groundbreaking advancement for industrial manufacturing, plasma "pens" are emerging as a game-changing solution for reducing equipment failure rates and enhancing production line reliability. These innovative tools leverage cutting-edge plasma technology to provide unprecedented surface treatment and quality control. Manufacturers are discovering that integrating plasma pens directly into production lines can dramatically improve component performance and longevity. By creating microscopic surface modifications, these advanced devices help eliminate potential weak points and contamination that traditionally lead to equipment failures. The technology works by generating a highly energetic plasma stream that can clean, activate, and modify surface properties of materials with remarkable precision. Unlike traditional treatment methods, plasma pens offer a non-contact, environmentally friendly approach that can be seamlessly incorporated into existing manufacturing workflows. Early adopters in aerospace, automotive, and electronics industries have reported significant reductions in failure rates—some seeing improvements of up to 40% in component reliability. As manufacturers seek more efficient and cost-effective quality control methods, plasma pen technology represents a promising frontier in industrial innovation. With continuous research and development, these plasma technologies are poised to revolutionize how industries approach surface preparation and equipment maintenance, offering a smarter, more precise path to manufacturing excellence. MORE...

Precision Revolution: How Advanced Pyrometers Are Transforming Manufacturing

Manufacturing

2025-02-20 14:20:00

As the landscape of high-tech manufacturing continues to evolve, precision temperature measurement has become a critical cornerstone of industrial innovation. Furnace technologies are increasingly driving advanced manufacturing processes, creating an urgent need for cutting-edge pyrometer research, breakthrough technological developments, and seamless connectivity solutions. The growing complexity of modern manufacturing demands sophisticated temperature monitoring systems that can deliver unprecedented accuracy and real-time insights. By investing in advanced pyrometer technologies, industries can unlock new levels of efficiency, quality control, and operational performance across diverse high-tech production environments. From semiconductor fabrication to aerospace engineering, the future of manufacturing hinges on our ability to develop more intelligent, responsive, and interconnected temperature measurement technologies. Researchers and engineers are now at the forefront of a technological revolution that promises to transform how we understand and optimize industrial heating processes. MORE...

Pharma Manufacturing Boom: Contract Market Projected to Skyrocket to $300 Billion by 2032

Manufacturing

2025-02-20 14:10:00

Pharmaceutical Contract Manufacturing Market Surges with Innovative Production Strategies and Cost Optimization

In a groundbreaking market analysis, the pharmaceutical contract manufacturing sector is experiencing remarkable growth, driven by strategic industry transformations and technological breakthroughs. Recent insights from SNS Insider reveal a compelling trajectory for this dynamic market segment.

Market Valuation and Projected Growth

The pharmaceutical contract manufacturing market demonstrated impressive financial performance, with a substantial valuation of USD 161.76 billion in 2023. Experts predict an extraordinary expansion, forecasting the market to reach an estimated USD 300.34 billion by 2032. This remarkable growth is underpinned by a robust compound annual growth rate (CAGR) of 7.15% between 2024 and 2032.

Key Growth Drivers

- Increasing demand for cost-effective drug production methods

- Continuous technological advancements in manufacturing processes

- Growing pharmaceutical outsourcing trends

- Enhanced focus on operational efficiency

The market's expansion reflects the pharmaceutical industry's strategic shift towards more flexible, innovative, and economically viable manufacturing solutions.

MORE...